Metal Seated Ball Valve

JXON is a professional manufacturer of metal seated ball valves. We can supply a variety types of metal seated ball valves. One special design feature of our metal seat is the inclusion of a dust removal system, which greatly extends the service life of our metal seated ball valves. Please do not hesitate to contact us for ball valve drawings, ball valve prices or any other details.

What is a metal seated ball valve?

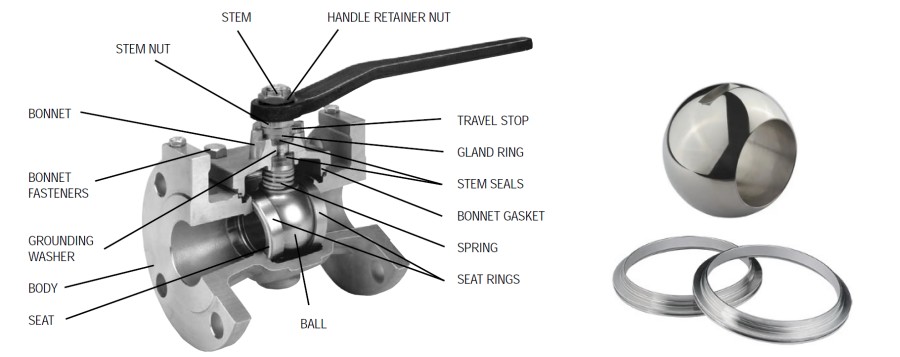

JXON metal to metal sealed ball valves are also known as hard sealed ball valves. Hard seal means that the valve ball and the seats are all made of metal materials. Metal seal work principle is the same as the soft seal.

The metal ball and seat will undergo a surface-hardening treatment. Generally, the ball and the seat of metal seated ball valves are coated with materials such as chrome carbide, Stellite, ultratek or other hard coatings. After the surface hardening treatment, there will be a grinding treatment. The grinding treatment can make the ball and metal seat have a good seal. In according to the advantages of the metal seat, metal seated ball valve usually used for high temperature and high pressure and medium with particle applications.

How do metal seated ball valves work?

JXON metal to metal seal ball valves are quarter-turn valves, when we switch the ball to the open position, it aligns with the metal seats and allows fluid to pass through. When we operate the ball to the closed position, the valve ball is perpendicular to the metal seats, and then the fluid is blocked.

Features of metal seated ball valves :

1.The ball and metal seats of the hard sealed ball valves require surface-hardening treatment. Because if coatings are not applied to the the ball and metal seat, the particle medium will immediately cause visible wear and tear. Typically, the damage worsens as the valve cycles until it becomes inoperable.

2.To handle applications involving abrasive catalysts, muds, slurries and powders, we typically apply hard coatings such as Tungsten Carbide, Stellite, ultratek or others onto the ball and metal seat. To increase the durability of the metal seated ball valve, there will be a slight difference in hardness between the coating on the ball and metal seat. As the ball has more contact with the medium, it's coating is harder than that of the metal seat. For example, when ball is coated with ultratek 60, the metal seat is coated with ultratek 55.

3.After coating process is finished, both the ball and seat need to be ground. This process can creat a smooth mirror surface on the ball and seat, resulting in lower torque and better sealing performance for the metal seated ball valve.

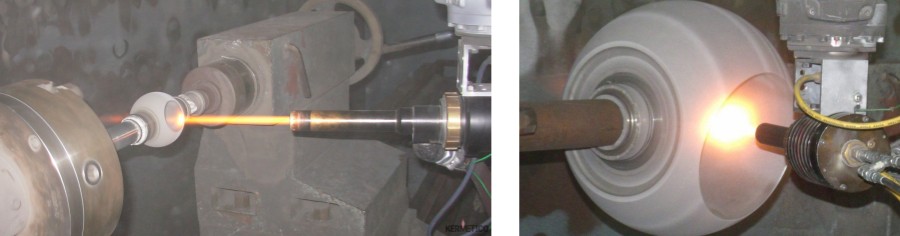

Surface hardening treatment

Grinding of balls and seats

Why should you choose JXON's metal seated ball valves?

Metal seated ball valves have advantages when used for media with particles and fibers in high temperature applications, such as coal chemical industry, boilers, scaling and freezing pipeline of power plants, and metallurgical industries. However, the traditional metal seat structure has many defects that greatly affect the valve's service life.

1.For traditional metal seat structures, the sealing surface is not wear resistant, and both the metal seat and ball are easily scratched by the medium.

2.The ball and metal seat are easily clogged by particulate matter.

3.The springs are unprotected and exposed to the medium. When the medium solidifies, particles entrapped within the springs will cause them to become stuck, resulting in seal failure.

4.The one-way seal structure will result in a large torque.

5.There are many requirements for installation of a one-way seal structure ball valve.

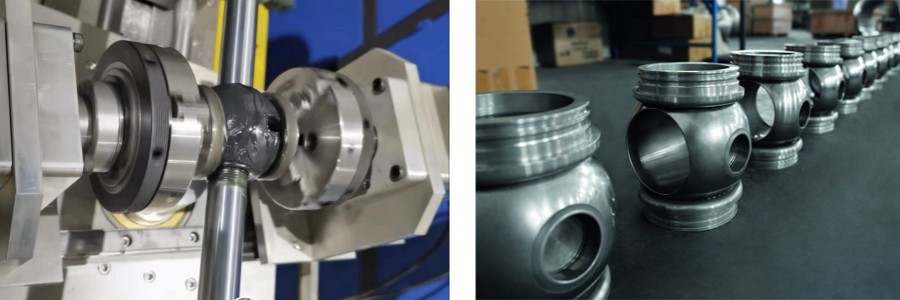

To solve the aforementioned problems, we have improve the metal seat structure as below:

1.We have adopted a two-way sealing design, so there is no need to consider the direction of the medium during installation. Additionally, the torque is lower than one-way seal structure.

2.Since Jxon metal seated ball valves have lower torque for the same size, they require smaller size actuator. This can result in significant cost savings.

3.To effectively prevent the medium from entering into the spring and solidifying, we have added a dustproof structure. This design has obtained a patent (Patent NO:CN209469823U). You can see in the following drawing our special metal seat , which prevents medium from entering the spring increases the service life of the metal to metal seal ball valve.

4.There is a cleaning function available for JXON metal seat. The seal surface is shaped like a blade, which can scrape off the medium from the ball while rotating it. This design prevents solid granules from entering the seat and damaging the sealing surface.