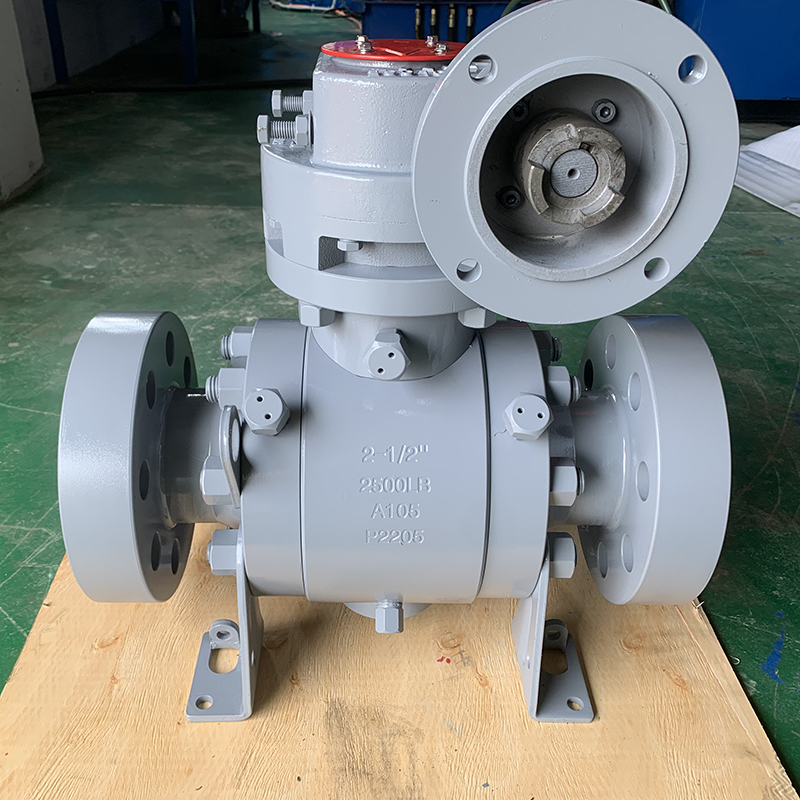

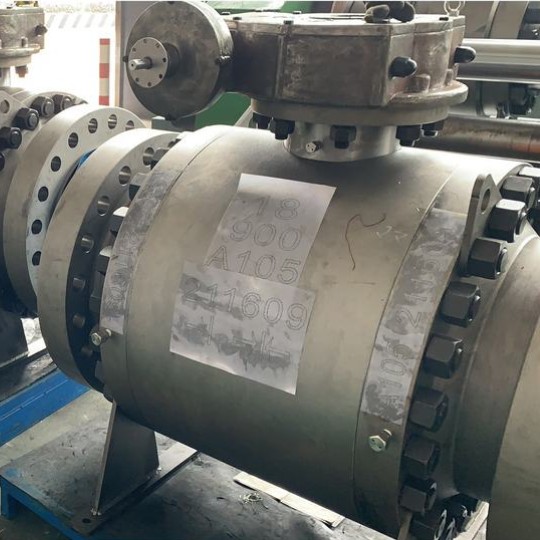

Forged Steel Ball Valve

JXON is a professional manufacturer of forged steel floating ball valves, offering a variety of options for you to choose from. Please contect us for more details, such as prices, drawings, and weight of forged steel floating ball valves.

What are forged steel ball valves?

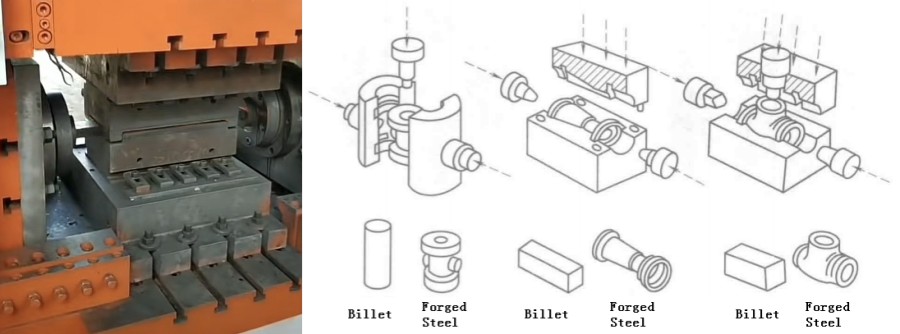

Jxon forged steel floating ball valves, which valve body is forged. Usually, there are two forging methods, one is produced using round steel, which is also known as open-die forging. The other method is produced using multi-directional die forging technology. As we know, the first forging method involves using a CNC machine to produce the round steel. However, this method is time -consuming and the cost of the raw material is very high. We recommend the second method of multi-directional die forging more.

We usually use carbon steel or stainless steel materials. Material such as A105, F304, F304L, F316, F316L are available. We will heat the billet to a certain temperature, and then place it into the mold. After that, we will compress the upper mold and lower mold together. The blank is extruded into the mold cavity by the left and right horizontal punches, resulting in the valve body we need.

How do forged ball valves work?

For a forged steel floating ball valve, the valve disc is a ball with round hole. The ball is held by the stem. When the stem is rotated under the drive of the handle or actuators, the ball will also rotate with it. When the ball rotates 90 degrees, the forged steel ball valve is fully open, allowing fluid to flow through with minimum resistance. When the ball rotates 90 degrees backward, the forged steel floating ball valve will be fully closed, cuting off the fluid flow.

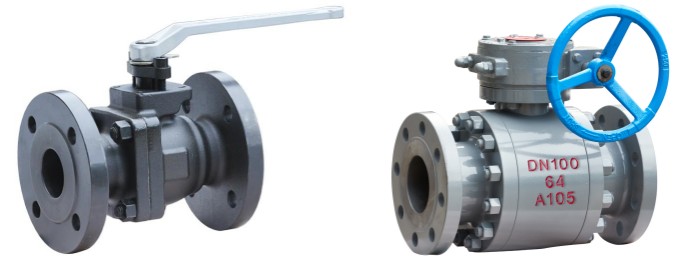

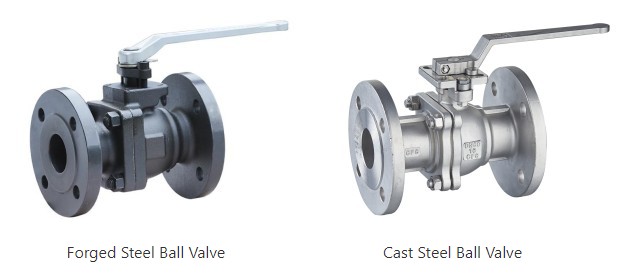

Forged steel ball valve VS Cast steel ball valve

Forged steel and cast steel are both wildly used in ball valves, but what are the critical differences between forged steel ball valve and cast steel ball valve?

1.During the heating and deformation process of the billet, the steel grains are displaced, leading to metallurgical recrystallization and grain refinement within the valve body. This enhances the impact and shear properties of forged steel valves, making them stronger and more reliable than cast steel valves.

2.The cast steel valve body may have problems such as non-uniform wall thickness, blowholes, and slag. In contrast, forged steel ball valves have uniform wall thickness and higher valve body performance.

3.Forged steel ball valves are more suitable for high pressure applications, which cast steel ball valves are better suited for large dimentions.

4.The cost of forged steel ball valves is higher than that of cast steel ball valves.

5.For the same size, forged steel ball valves have a thinner wall thickness than cast steel ball valves.

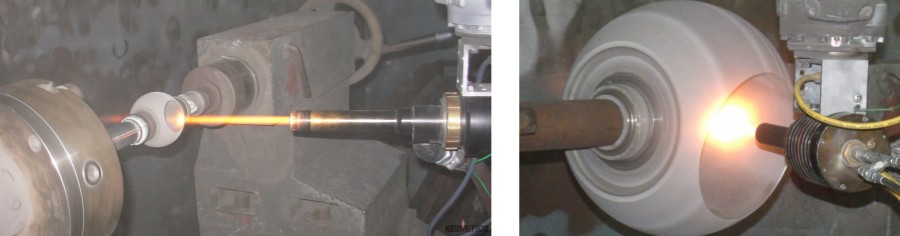

What is multi-directional die forging

1.Multi-directional die forging can produce blanks with complex shape, precise size, no burrs or forging slope, and with cavities that closely match the size and shape of finished parts, thereby improving material utilization rates for body and cover. Furthermore, this forging method can reduce machining man-hours of and significantly lower the cost of forgings.

2.For a multi-directional die forged valve body, there are no burrs, so there is no need to remove them. This is particularly important for the corrosion resistance of ball valves.

3.When open-die forging is used, the billet may crack due totensile stress within the steel. However, in multi-direction forging, the billet is always subjected to strong three-way stress and has high metal plasticity, which makes it easier to deform without breaking.

4.The forged steel ball valves which are made using multi-directional die forging technology, have a simple valve body structure. They also have a long service life, low manufacturing cost, and are convenient to use and maintenance. The multi-directional die forging molds are effective due to cooling and lubrication. Therefore, the mold can be used multiple times through proper maintenance, Which is beneficial for improving production efficiency and reducing forging costs.

5.Using multi-directional die forging technology has another significant feature: the steel can be shaped quickly. This multi-directional die forging technology is 5-30 times faster than open-die forging.

Productive process of forged steel ball valves

Application for forged steel ball valves

JXON's forged ball valves are suitable for various applications, with both soft seal and metal seal available.

1.Forged steel ball valve with a soft seal is usually used for applications involving natural gas and other flammable gases. Using a metal seal on a pipeline carring flammable gases can easy cause fire due to the heat produced by friction between the ball and the metal seat.

However, soft seals are prone to generate and accumulate static electricity. So two anti-static devices are installed on the stem.

Furthermore, the seat is designed to be fire safe. When a fire occurs inside the valve cavity, the soft seal will be damaged, causing the ball to connect with the seat groove. There is a slope surface that has been processed by the engineer's calculation. The slope will fit perfectly with the ball, preventing the spread of fire.

Furthermore, our stem is designed to be blowout proof. The stem is installed inside from the valve body with a T-boss design to prevent it from being blown out when the pressure inside the valve body is too high.

2.Forged ball valves with metal seals are typically used for granular media, such as slurry and powder.

To increase abrasion resistance and reduce friction, wear-resistant layers such as Tungsten Carbide, Stellite and Ultratek will be applied to the ball and metal seats.