Ball Valve

JXON is a professional and experienced industrial flanged ball valves manufacturer. We can supply stainless steel ball valves and carbon steel ball valves. Our most competitive product is closed-die forging flanged ball valves. Because we have our own independently developed fully automated drilling equipment to produce them. We not only have great price advantage, but also have short delivery time for it. We can export a complete set of ball valves, as well as ball valve components.

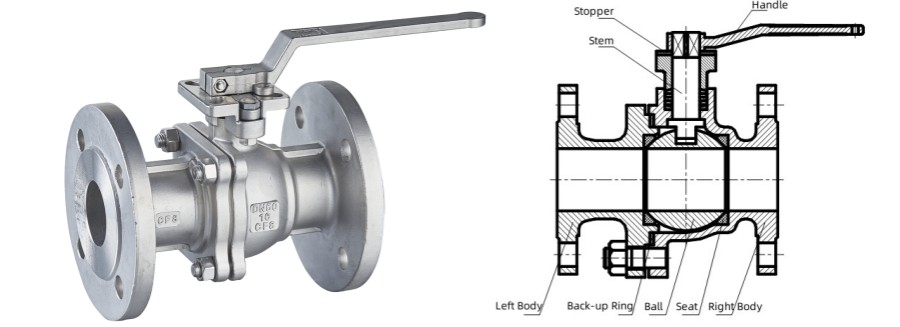

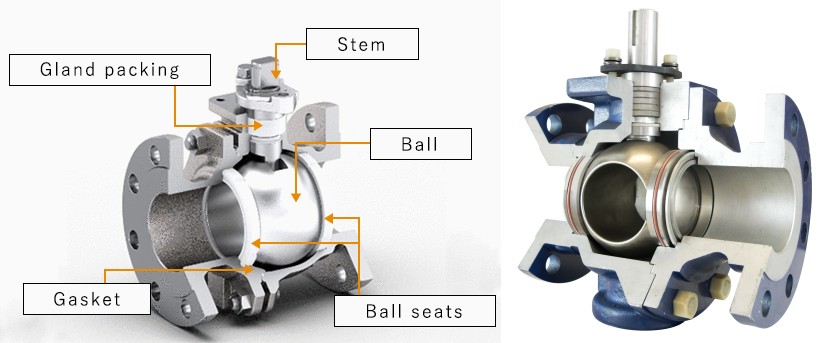

What is a ball valve?

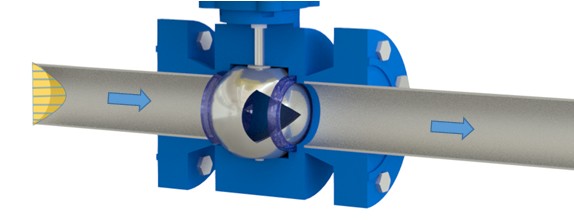

Ball valve is one of the most widely used valves. Ball valves were named after their valve disc is a ball. Ball valve structure includes valve body, stem, ball, seat and handle or actuator. The valve stem drives the rotation of the ball to control the opening and closing of the valve. The ball only needs to turn 90 degrees in order to cut off, distribute and change the flow direction of the medium. Ball valves are widely used in petroleum, long -distance pipeline, chemical, paper making, pharmaceutical, water treatment, electricity and other applications, which plays a pivotal role in the economy development.

How do ball valves work?

Because the ball is anchored to the stem, when the handle or the actuators drive the stem, the ball also rotates. When the angle of rotation of the ball increases, more fluid pass through the valve. When the ball is rotated 90 degrees, the valve is fully opened and fluid passes through with minimum resistance at this time. Similarly, when the ball is rotated 90 degrees backwards, the ball valve will be fully closed and the fluid flow will be cut off.

Types of ball valves

There are various types of ball valves, which can be classified in different ways, according to different classification approach.

1. Ball valves can be divided into different types based on the seat material used: soft seated ball valves and metal seated ball valves.

Soft seated ball valves

For a soft seated ball valve, the seat is usually made of soft material, such as rubber, nylon, PTFE and so on. Soft sealed ball valves are suitable for non-granular media, such as water, steam, natural gas, solvents and other medium. The soft seat will be easily damaged if it is used in a medium with particles.

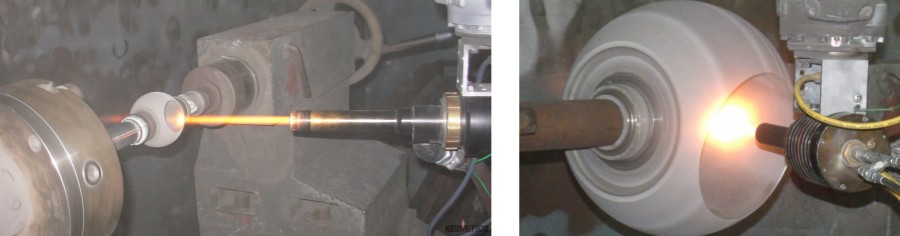

Metal seated ball valves

In a metal seated ball valve, the seat is made of metal. Metal seated ball valves are suitable for media containing particles, such as slurry, pulverized coal, ash and other similar substances. To increase the hardness and wear resistance, the ball and seats are typically coated with hard layers such as tungsten carbide, nickel base alloy and other wear resistant coatings. As we know, sealing between metal to metal is more difficult than the sealing between metal and soft material, therefore, in order to achieve a good seal between metal ball and metal seats, the sprayed ball and seats must be ground until they fit perfectly during operation.

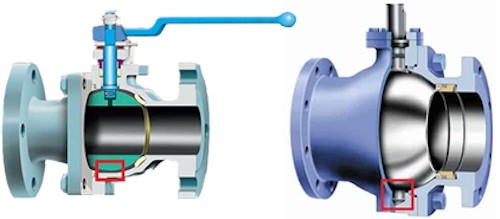

(The picture on the left shows a soft seated ball valve, while the picture on the right shows a metal seated ball valve.)

Spray hard layers to ball and seats

Grinding ball and seat

2. Ball valves can be classified into several types base on different actuators: ball valves with handle, ball valves with worm gear, pneumatic ball valves, electric ball valves, hydraulic ball valves, etc. We can install different actuators as per customer’s requirements and applications.

(The images below, from left to right, show manual ball valve, ball valve with worm gear, electric ball valve, pneumatic ball valve)

3. Ball valves can be divided into two types based on their different installation structures: floating ball valves and trunnion ball valves.

Floating ball valves

For floating ball valve, the ball may experience slight displacement under medium pressure due to being held only by the stem. Therefore it is called a floating ball valve. When the ball is displaced, it tightly connect to the outlet seat. The greater the medium pressure, the tighter the outlet seat sealing becomes. Due to its sealing characteristics, floating ball valves are commonly used in applications with medium and low pressure. If medium pressure is too high, it may damage the outletseat and increase the torque. For high pressure media, we usually use trunnion ball valves.

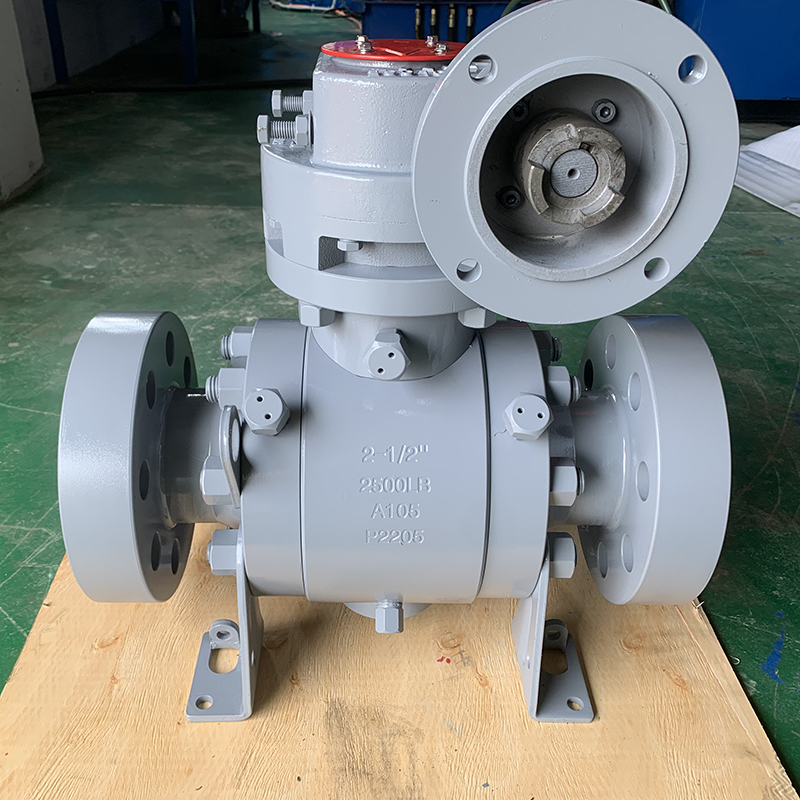

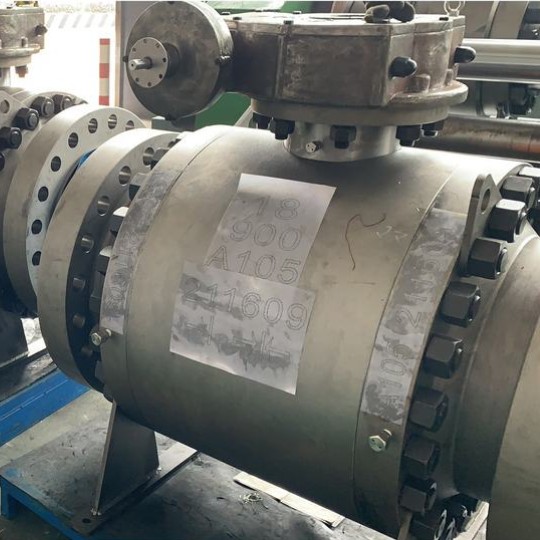

Trunnion ball valves

For a trunnion ball valve, the ball is fixed while the seats are floating. As shown in the pictures in the right below, the ball of the valve is held by a stem and trunnion, the fluid pressure is transferred to the stem and trunnion, which prevents displacement of the valve ball and make it easier to operate. Therefore, trunnion ball valves require less torque.

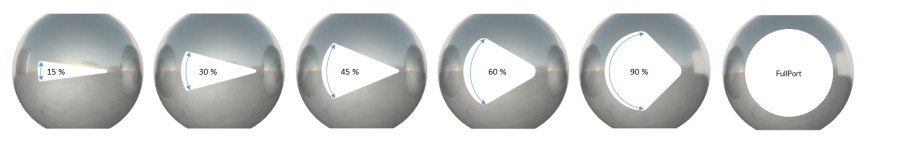

4. Based on the different shapes of the ball hole(which is also known as a port), ball valves can be classified into O-port ball valves and V-port ball valves. V-port ball valves are also called V-notch ball valve and segment ball valves.

For O-port ball valves, they usually adopt floating type, and for V-port ball valves, they usually adopt trunnion structure. The V-notch ball valves combine the shear function of gate valves and the fluid control function of globe valves, and the good sealing performance of common ball valves. V-notch ball valve is a versatile, high-performance rotary control valve designed for throttling, opening, and closing applications. It is a ball valve with an equal percentage flow feature. With a V-notch ball structure, the valve can effectively cut off viscous or granular media such as small particles, fibers and viscous slurry. The angle of the V-notch can be adjusted according to customer requirements.

5. Based on the materials used, our ball valves can be divided into carbon steel ball valves and stainless steel ball valves.

Stainless steel ball valves

We can provide you with carbon steel ball valves or stainless steel ball valves, depending on your specific requirements or working conditions. Stainless steel ball valves are suitable for use in both corrosive pipes and steam pipes. Because stainless steel ball valves have good corrosion resistance, high temperature resistance, and high pressure resistance. They are generally used for applications involving corrosive medium, water and food.

Carbon steel ball valves

For carbon steel ball valves, they can only be used for steam, oil, water and other Non-corrosive medium. Because the corrosion resistance of carbon steel is not as good as stainless steel, carbon steel ball valves usually require surface treatment such as blackening or painting to increase their corrosion resistance. The cost of carbon steel ball valves is much lower than that of stainless steel ball valves.

(The left side of the picture shows a blackened carbon steel ball valve, and the right side shows a stainless steel ball valve with an untreated surface)

6. Ball valves can be divided into two types based on different processing techniques: cast steel ball valves and forged steel ball valves.

It is difficult to determine which one is superior as they each have unique advantages. The primary distinction between cast steel ball valves and forged steel ball valves lies in the valve body's forming process.

Cast steel ball valves

For cast steel ball valve, the casting process involves pouring molten steel into a mold and allowing it to cool before demolding to obtain the valve body raw material. We can cast ball valves with complex shape and large diameters, and for the raw material of cast steel valve body, a simple CNC machining process is all that's needed to obtain the finished product. However, the casting process is more complex than the forging process due to the lengthier time required for making the mold, pouring and cooling of the valve body.

Forged steel ball valves

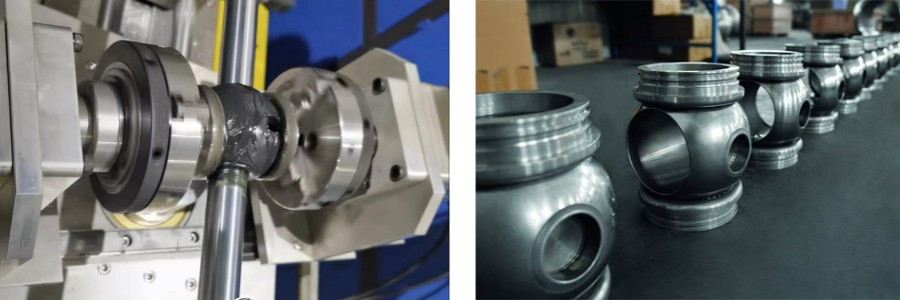

Customers may choose forged steel ball valves for high strength and high pressure applications. In the case of forged steel ball valves, the valve body is formed by placing the billet into a mold and extruding through the pressure equipment. The molding time is short, but the follow-up procrssing time for forged steel ball valve bodies is longer than that for cast steel valve bodies due to the presence of more residual materials.

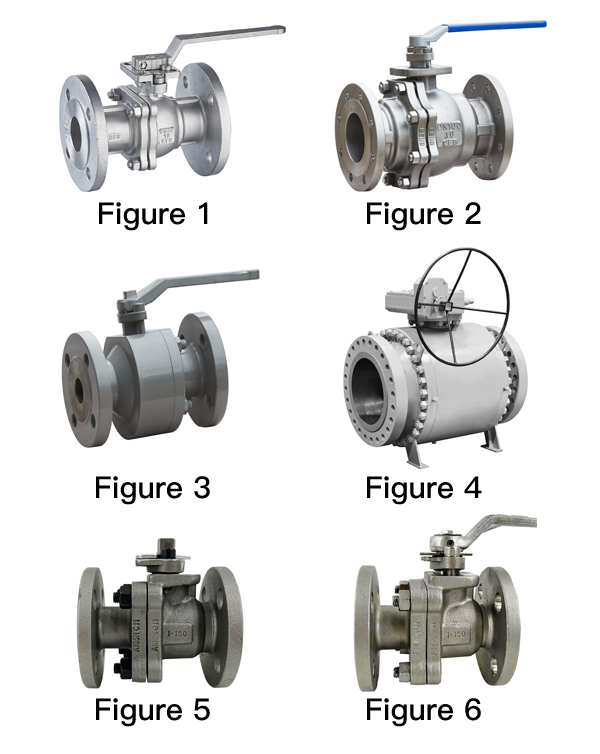

Do you know how to distinguish between cast steel ball valves and forged steel ball valve?

Let’s do a little test! There are six pictures below, please identify the forged steel ball valves and cast steel ball valves. ^-^

The answer is that Figure 1 and 2 are cast steel ball valves, and Figure 2 to 6 are forged steel ball valves. Did you get it right? ^-^

Let me show you some simple ways to distinguish it, as shown below:

a. For cast steel ball valves, they usually have strengthening ribs on the valve body to reinforce it. However, this is not always the case as some cast steel ball valves may lack these reinforcing ribs. Additionally, the surface of the cast steel ball valve surface is overall smooth.

b. The judgment method for forged steel ball valves differs due to variations in the forging process. For round forged steel ball valves, as shown in Figure 3 and Figure 4, the valve body can be made of round steel and produced by CNC machine. Furthermore, it can also be produced through open-die forging or ring forging. From its appearance, it is easy to distinguish that this round body ball valve is made of forged steel.

There is another forged steel ball valve that is difficult to distinguish from the appearance, just like Figure 5 and Figure 6. The valve body of these forged steel ball valves is formed through multi-direction die forging process, which is also known as closed-die forging. For this ball valve, you can identify it base on following two points. Firstly, we can see that forged steel ball valves do not have strengthening ribs on their bodies. Secondly, the surface finish of it is different. You can see in following pictures that the flanges show a delicate surface after being processed by CNC machine, while the surface of valve body is not as delicate after acid pickling or shot blasting.

The advantage of close-die forging is that it can mold the complex valve body in one step with minimal waste material, similar to a cast valve body. The valve body produced by closed-die fordging has a short forming time, accurate size, no forging inclination, and includes a cavity. The shape and size of valve body maximally close to that of the finished parts, which can improve the material utilization rate of both the ball valve body and cover. This forged steel ball valve is one of our advantaged products. Compared to a round forged steel ball valve, this forged steel ball valve has lower cost and shorter delivery time. Compared to a cast steel ball valve, this forged steel ball valve has a stronger valve body.

7.Ball valves can be classified into two types based on their different installation directions: top entry ball valves and side entry ball valves.

It is very easy to distinguish between top entry ball valve and side entry ball valve based on their appearance. Please refer to following two pictures: the left one shows a side entry ball valve, while the right one shows a top entry ball valve.

Top entry ball valves

For a top entry ball valve, the valve body is one piece with a cap above it. The ball and seats are installed from the top of the valve body.

Side entry ball valves

For a side entry ball valve, the valve body can be divided into two or three pieces. The ball is assembled from side of the valve body. The side entry ball valve has a simple structure, making it convenient for manufacturing and installation. It is suitable for small diameter applications, especially those incolving viscous or easy crystallization media.

Summary

JXON offers a wide range of ball valves, each with different features and advantages. Different types of ball valves should be chosen for different working conditions.

Although different ball valves may have similar use, it is critical for piping designers to be aware of the benefits and drawbacks of each design type. Depending on your specific application and budget, JXON team are willing to help you decide which type of ball valve will work best for you.

FAQ

Q: Are you a trading company or a manufacturer?

A: Yes, we are a professional ball valve manufacturer and can offer you the best price.

Q: Can you do OEM manufacturing?

A: Yes.

Q: What about the packing?

A: Normally, we pack ball valves in plywood cases.

Q: What is the minimum order quantity (MOQ)?

A: The amount money for one order needs to be greater than 1000 dollars and the quantity of one size product needs to be greater than 10pcs.

Q: What are the payment terms?

A:30% of the payment is required as a deposit, and the remaining balance must be paid before shipment.

Q: Are samples available?

A: Yes.