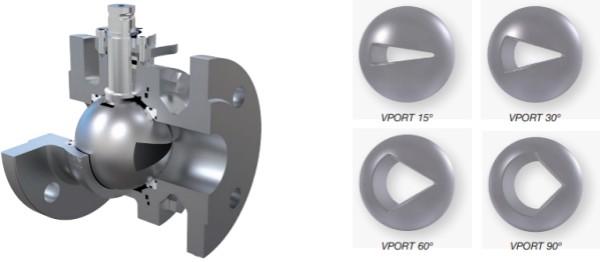

V-port Ball Valve

JXON is a professional ball valve manufacturer. We can supply V-port ball valves and O-port ball valves. Which are exported to many countries including Europe, Mid-Est, Asia, America market, Africa, etc. For more detailed information on our V-port ball valves, please feel free to contact us.

What is V-port ball valve?

A V-port ball valve can also be referred to as a V-notch ball valve, because the ball insided the valve cavity has a port in the shape of a "V". The V-port ball valve is a high performance control valve with multi-functions, as it combines the shear fuction of a knife gate valve, the precise control function of a globe valve, and the excellent sealing performance of a traditional ball valve. The V-port structure is mainly designed for throttling and switching applications.

For a V-notch designed structure, when the valve is closed, it can shear particles, fibers, viscous slurry and other media. V-port ball valves can be classified into floating V-port ball valves and trunnion mounted V-port ball valves. V-port ball valves are widely used in many industries, such as the papermaking and pulp industry, refineries and petrochemical services applications. The segment ball valve is economical and durable.

V-port ball valve: How does it work?

The segment ball valve is similar to the traditional ball valve, as they both have a ball as the switching component in the valve cavity. The difference between traditional ball valves and segment ball valves is that the former has a round access, while the latter has a V-notch on the ball. The V-notch ball rotates under the drive of the valve stem, as the ball rotates, the fibers and solid material in the medium are cut off by the knife-edge shape of the V-notch. The traditional ball valve does not have a shear function, so it can easily become stuck by fibrous impurities, leading to the difficult maintenance. In contrast, the v-notch ball valve allow for flow adjustment and control through changes in the opening area.

Segment V-notch Ball Valve

Type of V-port ball valve:

1.V-port floating ball valve

The ball of segment floating ball valve is floating, so it will have a small displacement under medium pressure. The displacement allows the ball to connect tightly with the seat. The V-port floating ball valve provides two-way sealing and has no restrictions on media flow.

2.V-port trunnion ball valve

Compared to the V-port floating ball valve, the ball of V-port trunnion ball valve is fixed while the seat is floating. V-notch ball valves are generally single ealed ball valves, so they are one-way flow, the valve body adopt integral body structure, there is no potential for leakage. For the V-notch structure, if it is pressed against the seat for a long time, the seat may easily wear. To protect the seat, V-notch ball usually has an eccentric design. During the opening process of the ball valve, pressure on the seat gradually decreases until it is completely sealed with the seat when closed. This structural design increases the service life of V-port valves.

V-port ball valve features:

1.The V-port ball valve is a quarter-turn ball valve that shares characteristics with the globe valve.

2.The smooth flow of the medium helps reduce erosion of the valve caused by cavitation and turbulence.

3.The V-notch and valve seat generate a strong shear force to cut off fiber impurities, while the self-cleaning function prevents valve blockage.

4.The eccentric structure reduces the contact between the ball and the seat, which can decrease wear on the sealing surface.

5.The V-notch ball valve has a compact structure. For trunnion V-notch ball valve, it usually adopts a floating single metal seat, which provides superior sealing performance and long service life.

6.The trunnion segment V-notch ball valve, holds the ball in place with its stem and trunnion, resulting in low operation torque.

V-port ball valve VS traditional O-port ball valve

1.The access of V-port ball valve is through a V-notch, which is shaped like a blade and cut off fibers or slurry to prevent the ball from getting stuck by the medium. Traditional ball valves have a round access and do not process the function off the medium.

2.V-notch trunnion ball valve is usually a one-way seal, while traditional trunnion ball valve can be bidirectional.

3.For the same size ball valve, V-port valves are more cost-effective than traditional ball valves.

4.For the same size, V-notch valves are lighter than traditional ball valves.