Trunnion Ball Valve

JXON is a professional manufacturer of trunnion ball valves. Trunnion ball valves compensate for the limitations of floating ball valves and are more suitable for high temperature and high pressure applications.

What is a trunnion ball valve?

Jxon Trunnion Ball Valves have a two-piece body or three-piece body design, which includes a ball with a hole in the center. Our trunnion ball valve is typically used for applications that require large diameter and high pressures. They are generally operated by handwheel, worm gear, pneumatic actuator, electric actuator and hydraulic actuator.

As its name suggests, a trunnion ball valve has a trunnion mount on the ball valve. As we know, for a floating ball valve, the valve ball is only fixed to the valve stem. When operating the valve, the valve ball will shift slight under pressure from the medium. In high pressure applications, this structure will have a high operating torque for the ball valves and the ball is also prone to deformation. In this case, the designer has added a trunnion mounted at the bottom of the valve ball so that it will be held in place by both stem and trunnion mount. For this trunnion mounted design, the fluid pressure will be transferred to the stem and trunnion. As a result, the valve ball will not experience displacement and will be easier to operate with less deformation. Trunnion ball valves are available in various sizes and pressure ratings to meet the needs of different industries.

How do trunnion mounted ball valves work?

Jxon trunnion ball valves are quarter-turn valves that share many similarities with floating ball valves. When the valve is in the open position, the hole of the ball aligns with both the inlet and outlet of the valve, allowing fluid to flow through. When the valve ball is rotated 90 degrees backwards, it will be in the closed position. At this point, the hole of the ball no longer aligns with the inlet and outlet of the valve, effectively blocking fluid flow.

Types of trunnion Ball Valves

1. Trunnion ball valves can be classified into two types: two piece trunnion ball valves and three piece trunnion ball valves.

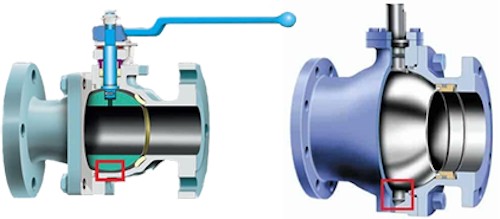

It is easy to disdinguish them by their appearance. Please refer to the following two pictures. The left one shows a two piece trunnion ball valve, and the right one shows a three piece trunnion ball valve.

The structure of a two piece trunnion ball valve is very simple, making it suitable for small dimensions applications. Two piece trunnion ball valves are lighter in weight than three piece trunnion ball valves of the same dimension, making them easier to install.

Three piece trunnion ball valves are typically used for high pressure and large dimension applications. The valve body is usually forged, and its appearance is simple and beautiful.

2. Trunnion ball valves can be classified into two types based on the different seats they have: soft seated trunnion ball valves and metal seated trunnion ball valves.

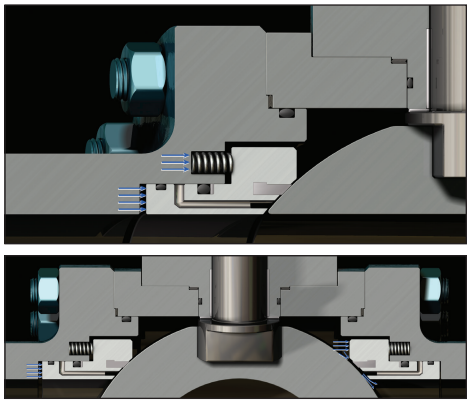

For trunnion ball valves, the ball is fixed while the seats are floating. Both soft seat and metal seat require springs on the seat, the elasticity of the springs can maintain good sealing between the seat and ball under any pressure condition.

Soft seated trunnion ball valves VS Metal seated trunnion ball valves

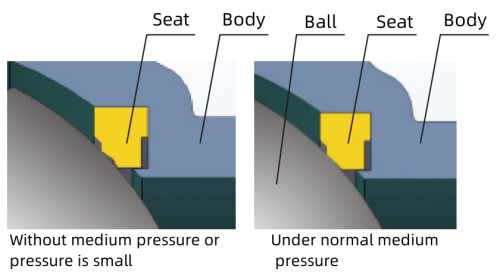

Soft seats are made of soft materials, such as PTFER, PTFE, PPL, PEEK and other composite materials. These seats are contained within a one-piece metal seat ring. When there is no pressure or the pressure is low, the sealing between the soft seat and the ball is achieved through the elastic force of springs. When the pressure in the pipe increases, the medium pressure and seat springs work together to ensure good sealing.

Metal seated ball valves, also known as metal to metal sealed ball valves, have sealing surface made of metal material. During the operation of metal seated ball valve, their is significant friction between the ball and the metal seat, which can result in valve wear. If the seat becomes worn, it may cause seal failure. Therefore, to reduce wear on the ball and metal seat, we need to spray hard materials onto them to increase their hardness. As we know, metal to metal sealing is more difficult than soft sealing. Thus, to ensure a good seal between the ball and metal seat, they need to be ground until the ball and the seat can be completely sealed.

How to choose between soft seated trunnion ball valves and metal seated trunnion ball valves?

The soft seated trunnion ball valve is suitable for media that do not contain particulate matter, and the medium temperature cannot exceed the maximum temperature of the soft seat. Additionally, due to its low strength, the soft seat is commonly used in medium and low pressure applications such as water, air, natural gas, steam, and some corrosive media. However, an anti-static device must be installed on the ball valve due to the large amounts of static electricity generated by friction between the ball and soft seat, which may cause a fire.

The seat of the hard sealed ball valve is made of metal material. Metal seats have high strength, making them suitable for media containing particulate matter and high temperature and pressure applications. Such as petroleum, coal, fibers, slurries, thick and corrosive media, and other media containing particles.

(Please refer to the following pictures. The seat on the left is metal seat, while the one on the right is a soft seat.)

Structure features of trunnion ball valves

1.Trunnion mounted structure with low torque.

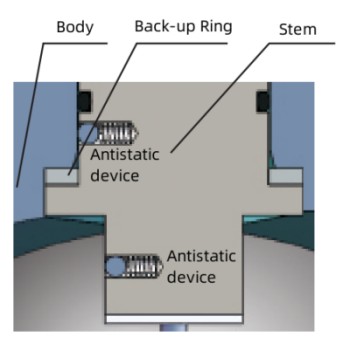

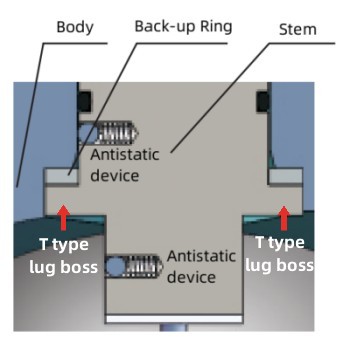

2.Two antistatic device: we have two antistatic devices in the stem: one between the ball and the stem, and the other between the valve body and the stem. This design can prevent potential hazard caused by static electricity accumulation.

3.Fire safe: We have a Triple Fire Safety System. If a fire occurs inside the valve body, the soft seat will be damaged and the metal seat and ball will form a tight seal under spring pressure. This design will effectively prevent the spread of fire.

4.Our fire safe valves are designed in accordance with the standards of API 607, API 6FA, and EN ISO10497.

5.Blowout-proof stem: Our stem is installed inside the valve body, and the part of the stem within the valve body is designed as a "T"-shaped lug boss. On the one hand, the "T" design can prevent blowouts, on the other hand, when there is pressure from inside the valve, the stem and back-up ring creat a tight seal that effectively prevent leakage from the valve body.

6.Lip seal design: we have designed a special "U"-shaped soft seat with a low sealing pressure ratio when the valve has low pressure and a high sealing pressure ratio when the valve has high pressure. For a valve, which generally works under low and high pressure, seat tightness may gradually weaken. Our "U" type design compensates for the weakened seal.

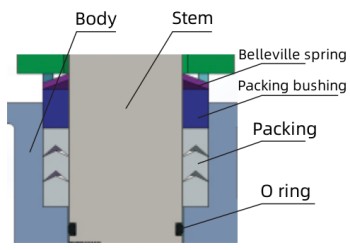

7.Triple Mechanical Seal System of stem: Firstly, there is an O-ring on the stem that provide the first seal. Secondly, we use the "V"-type packing around the stem. The "v"-shaped packing undergoes a change in shape when pressure is applied by the cap, allowing it to it provide a secondary seal. Thirdly, we add a belleville spring above the packing bushing. When the packing is deformed under high pressure, it can prevent the leakage under low pressure.

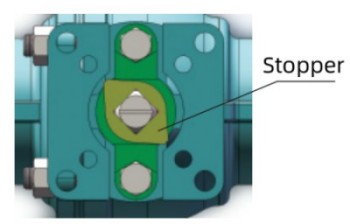

8.Anti misoperation switch function: There is a stopper that can be rotated 90 degrees. When the handle is parallel with the pipe, the ball valve is open. When the handle is perpendicular to the pipe, the ball valve is closed, which can prevent misoperation.

9.For Trunnion ball valves, there are two options for sealing: soft seal and metal to metal seal. Soft Seal, there is a double seals structure. The primary soft seal is silicone, and the secondary soft seal is PTFE. When the silicone wears out, the PTFE will take over.

10.For metal to metal seals, the ball and seat are surfaced with materials such as nickel 60/ nickle 55 or tungsten carbide. There is a slight difference in hardness between the valve ball and seat spray, which can prevent the ball from getting stuck on the seat.

Trunnion Ball Valve VS Floating Ball Valve

There are two main types of ball valves: floating ball valves and trunnion ball valves. Both types have their own unique features, but what is the difference between them?

1.The trunnion ball valves are sealed by the spring-loaded seat float. While the floating ball valves are sealed downstream by the pressure of the media on the ball valve.

2.The trunnion ball valves are suitable for high pressure and high temperature applications, while floating ball valves are more appropriate for low and medium pressure and low temperature applications.

3.The trunnion ball valves are usually used for large size valves, while floating ball valves are typically used for small sized ones.

4.The trunnion ball valves typically have a large volume, making them difficult to move and install. However, floating ball valves have a simple structure, making them easy to install and maintain.

5.Trunnion mounted ball valves are typically more expensive than floating ball valves.

6.Trunnion ball valves require less torque compared to floating ball valves.

In conclusion, both types of ball valves have advantages and disadvantages, so it is essential to select the suitable one for a specific application. Please feel free to contact us to choose the suitable valves.

Why choose a JXON trunnion mounted ball valve?

1. JXON trunnion ball valves are strictly produced and inspected in according with the ISO9000 quality control system.

2. JXON trunnion ball valves will undergo inspection according to API598/DIN3230/EN12266-1 inspection standards before shipment.

3. JXON trunnion ball valves come with a comprehensive after-sales service process. If you have any questions regarding the trunnion ball valves, we will provide you with effective solutions promptly.