Top Entry Ball Valves

JXON is a professional manufacturer of top entry ball valves and side entry ball valves. The working principle of top entry ball valves is very similar to that of side enrty ball valves, with the biggest difference being the installation method of the ball and seats.

What is a top entry ball valve?

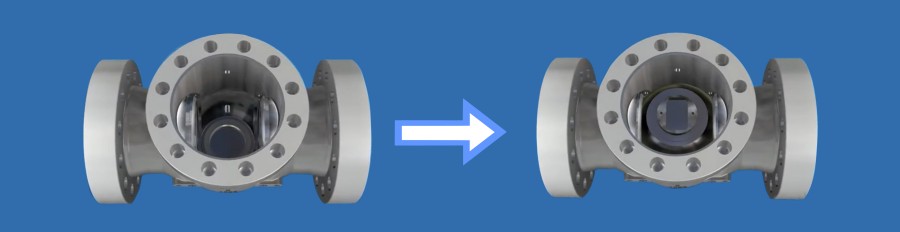

In a top entry ball valve, the ball and seat are assembled from the valve top, and the valve body is one piece. Therefore, there are fewer leakage points compared to side entry ball valves. The biggest advantage of top enrty ball valves is that they can be maintained without removing the valve from the pipeline. When the top entry ball valve needs to be repaired, it does not need to be removed. We only need to remove the cap and valve stem from the top of the valve, and then take out the ball and seat. Therefore, it requires less maintenance and shutdown time for pipelines. Top entry ball valves are widely used in applications such as oil and gas pipelines, oil production, refining, petrochemicals, chemical fibers, metallurgy, electric power generation, nuclear power plants, food processing and papermaking.

How does the top entry ball valve work?

A top entry ball valve has a ball with a circular channel in the valve cavity as its opening and closing component. The ball can be rotated by the valve stem, allowing the valve to open and close around an axis perpendicular to the channel.

How to assemble the top entry ball valve?

Top entry ball valves are widely used in oil and gas pipelines, as well as oil production, refining, chemical and petrochemical industries, metallurgy, electric power generation, nuclear power plants, food processing and papermaking applications. Since the ball and seat are assembled from the valve top, the seat should be assembled before assembling the ball. To facilitate the assembly of the ball, the outer edge of the seat and the spring seat need to be turned separately. The spring shoud then be pressed into the spring seat with an adjusting nut before fitting the seat assembly into the body. Because the valve seat spring has been compressed previously, it is very easy to assemble the ball. When the ball is assembled, pull the adjusting nut out of the spring seat. At this moment, there will be a slight pre-tightening force on the ball from the spring, allowing for a tight connection between the valve seat and ball. Furthermore, adjusting the adjusting nut on the seat can increase the pre-tightening force of the spring. Finally, assemble the stem and cap to complete assembly of the top entry ball valve.

Types of top entry ball valve

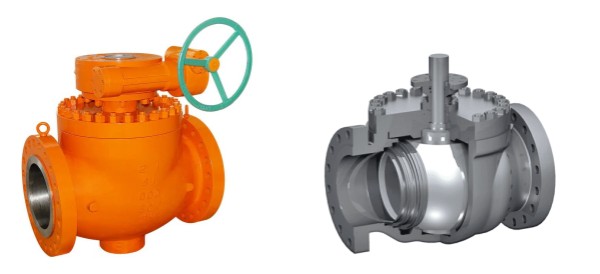

For top entry ball valves, they can be floating type and trunnion type.

1.Top entry floating ball valve

For top enrty floating ball valves, the ball is designed to float. When media pressure is applied, the ball will have a small displacement and connect to the outlet seat, ensuring a good seal at the outlet end. Floating ball valves are typically characterized by their small volume, light weight and simple structures.

2.Top enrty trunnion ball valve

For a top entry trunnion ball valve, the ball is held in place by the trunnion, ensuring that it reamains stationary under pressure. However, due to the floating valve seat, it may displace under medium and spring pressure, allowing for a tight connection with the ball. The top entry ball valve with a trunnion structure usually requires small torque, making it highly suitable for high pressure and large diameter valves.

Top entry ball valve VS Side entry ball valve

Ball valves can be divided into top entry ball valves and side entry ball valves based on the different installation methods of the ball. Because of the different installation mathods, top entry ball valves and side entry ball valves have their own advantages and disadvantages.

1.For top entry ball valves, the valve body being one piece means that the ball and seat must be installed from the top, making assembly more difficult than with side enrty ball valves.

2.Although the assembly of top entry ball valves is more difficult, they are easier to maintain than side entry ball valves.

3.Top entry ball valves are typically used in process systems where in-line maintenance is preferred over full valve removal. Therefore, top entry ball valves are commonly utilized in high-pressure applications that require infrequent maintenance, such as high integrity pressure protection system (HIPPS) valves.

4.Both top entry ball valves and side entry ball valves can be of the floating or trunnion type. Trunnion type ball valves can reduce the valve torque.

Top entry ball valve features

1.It is suitable for frequent use because it can be quickly and easily opened and closed.

2.A structure with full diameter and low fluid resistance.

3.On-line maintenance

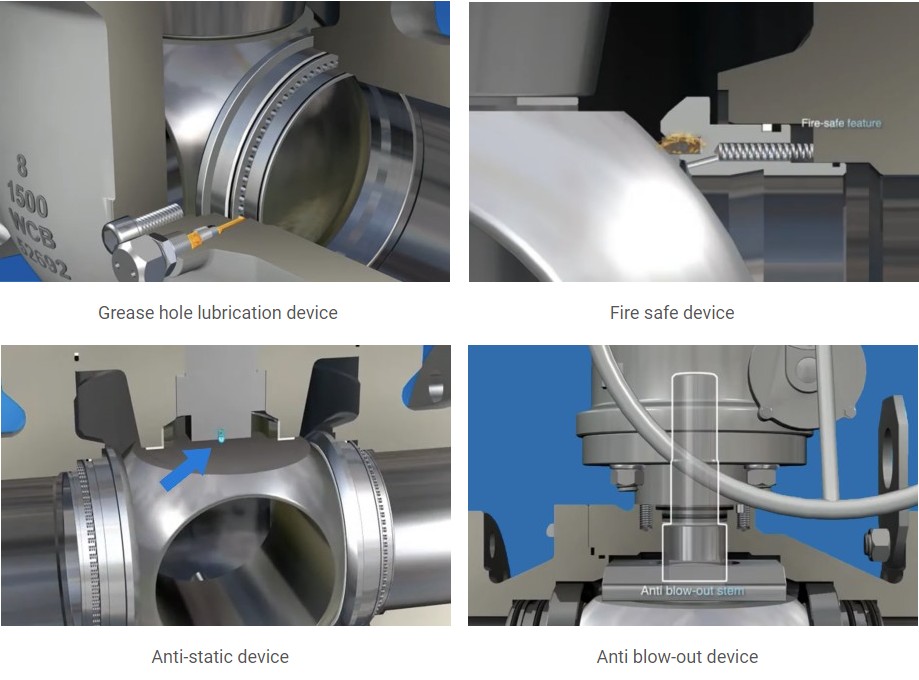

3.Fire safe device

4.Blow-out design

5.Bidirectional seal

6.Grease hole lubrication device