Metal Seated Floating Flanged Ball Valve

JXON is a professional ball valve manufacturer. We can supply metal seated floating flanged ball valve. In order to meet the needs of different customers, we can export both complete ball valves and ball valve parts.

- Port size :

- DN15~DN200 (1/2"~8")

- Pressure :

- 150LB~600LB

- Structure :

- 2PC

- Medium :

- particles, such as slurry, pulverized coal, ash and other medium

- Temperature :

- -29 ℃~425 ℃

- Body material :

- WCB, CF8, CF8M Stainless Steel

- Connection :

- Flanged End

- Feature :

- Floating Type, Metal Seated, Metal to Metal sealed

Metal Seated Floating Flanged Ball Valve

JXON Valve Co., Ltd is a manufacturer of metal seated ball valves. We can supply both metal seated floating ball valves and metal seated trunnioin ball valves. They are widely used for various applications, especially for granular media and high pressure situations. Floating ball valves have a ball that floats on a seat, which reduces the risk of damage from friction.

How does metal seated floating flanged ball valves work?

The JXON metal seated floating ball valve is entirely made of metal materials for both the ball and seat. When the ball valve is operated, the valve ball will experience a slight displacement due to the pressure of the medium. Then the ball will connect tightly to the metal seat of the outlet. Metal seated floating ball valves are a good choice for fluid control.

Standard specification for design and manufacture of metal seated floating ball valves

| Nominal Diameter | NPS1/2"-8" (DN15-DN200) |

| Nominal Pressure | 150LB~600LB |

| Manufacturer's Standard | ASME B16.34 API 608 API 6D |

| Structure Length | ASME B16.10 |

| Flange | ASME B16.5 |

| Inspection Standard | API 598 |

| Valve Body Material | WCB, WCA, WCC, WC5, WC6, WC9, LCB A105, F304, F316, F51, 2205 CF3, CF8, CF3M, CF8M |

| Sealing Material | Hard Chromium Plating, Spray Ni60, overlaying STL(Stellite) Spary WC(Wolfram Carbide) |

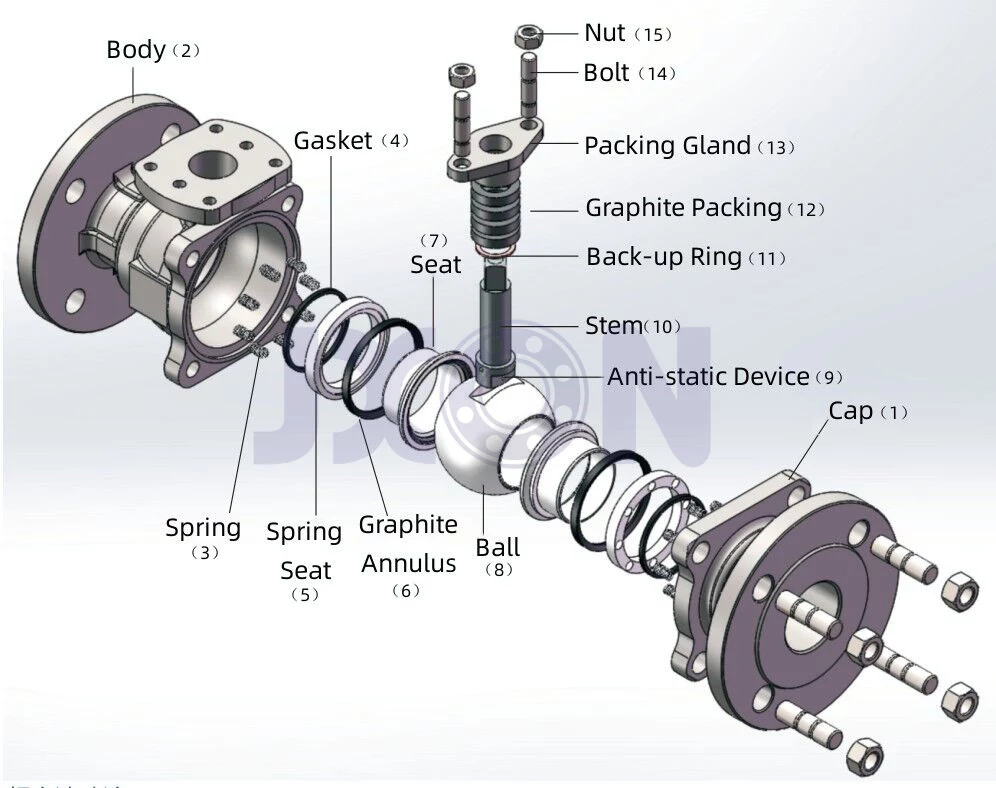

Materials of metal seated floating flanged ball valves parts

| No. | Name of Part | Carbon Steel Series | Stainless Steel Series | Low Temperature Steel Series |

| 1 | Cap | A105 | F304/F316 | LF2/F304/F316 |

| 2 | Valve Body | A105 | F304/F316 | LF2/F304/F316 |

| 3 | Spring | 304, 316L, 17-7PH, X-750, 60Si2MnA | 304, 316L, 17-7PH, X-750, 60Si2MnA | 304, 316L, 17-7PH, X-750, 60Si2MnA |

| 4 | O-Ring Gasket | Silicone | Silicone | Silicone |

| 5 | Spring Seat | A105, 304 | 304/316 | 304/316 |

| 6 | Graphite Annulus | Graphite+304/316 | Graphite+304/316 | Graphite+304/316 |

| 7 | Seat | A105, 304 | 304/316 | 304/316 |

| 8 | Ball | A105+HCr/ENP | A182 F304/F316 | A182 F304 |

| 9 | Antistatic Device | Stainless Steel+Spring | Stainless Steel+Spring | Stainless Steel+Spring |

| (防静电装置) | ||||

| 10 | Stem | A182 F6a | A182 F304/F316 | A182 F6a |

| 11 | Back-up Ring | 304/316/Copper | 304/316/Copper | 304/316/Copper |

| 12 | Graphite Packing | Graphite | Graphite | Graphite |

| 13 | Packing Gland | A105 | F304/F316 | LF2/F304/F316 |

| 14 | Bolt | A193 B7 | A193 B8/B8M | A320 L7 |

| 15 | Nut | A194 2H | A194 8/8M | A194 7 |

Main performance specifications of metal seated floating flanged ball valves

| Nominal Diameter (CL) | CL150 | CL300 | CL600 | CL900 | |

| Test Pressure | Body Strength | 3.0Mpa | 7.5Mpa | 15.0Mpa | 22.5Mpa |

| High Pressure Seal (Water) | 2.2Mpa | 5.5Mpa | 11.0Mpa | 16.5Mpa | |

| Low Pressure Seal(Air) | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Suitable Temperature | -29℃~425℃ | ||||

| Media | Air, Steam, Water, Oil, Acid, Alkali, Salt, Etc.(media without excessive particle impurities.) | ||||

| Drive Mode | Handle, Worm Gear, electric actuator, Pneumatic Actuator, Hydraulic Actuator | ||||

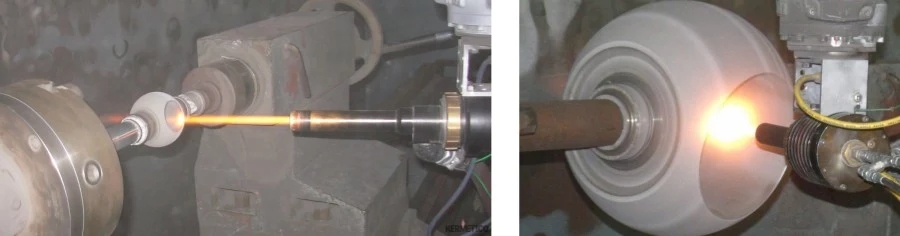

Supersonic spray of metal seated floating ball and seat (HVOF,HVAF)

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.5-1.2mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.5-1.2mm |

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.4-0.8mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.4-0.8mm |

| Wolfram Carbide | HV950-1400 (HRC68-76) | Coating Thickness 0.15-0.25mm |

| Chromium Carbide | HV850-1150 (HRC66-72) | Coating Thickness 0.15-0.25mm |

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.15-0.25mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.15-0.25mm |

Standard of metal seated floating flanged ball valves

| Standard Specifications for ANSI CLASS 150/600 Flanged Ball Valve | |

| Design and Manufacture Standard | API 6D/ASME B16.34 |

| Wall Thickness Standard | API 6D/ASME B16.34 |

| Face-to-Face Dimension Standard | API 6D/ASME B16.34 |

| Flange End Dimension Standard | ANSI/ASME B16.5 (1/2” to 2”) |

| Inspection & Testing Standard | API 6D/API 598 |

| Fire Safe Design Standard | API 607/BS 6755 |

| Material Standard | Nace MR 0175 |

| Standard Specifications for DIN PN16/40 Flanged Ball Valve | |

| Design and Manufacture Standard | EN1983, EN12516-1 |

| Flange End Dimension Standard | DIN2543-2545, EN1092-1, PN16/40 |

| Face-to-Face Dimension Standard | DIN3202-F1, EN558-1 |

| Inspection & Testing Standard | DIN3230, EN12266-1 |

Features of metal seated floating flanged ball valves

| Full Port | 1/2"-2"(DN15-DN50) |

| Flanged End Working Pressure | PN16/160, Class 150/900 |

| Handle with Lock Device | Optional |

| ISO5211 High Platform | Optional |

Valve body temperature of metal seated floating flanged ball valves

| Carbon Steel Valve Body(WCB) | -30℃~425℃ |

| 304 Stainless Steel Valve Body | -268℃~649℃ |

| 304L Stainless Steel Valve Body | -268℃~649℃ |

| 316 Stainless Steel Valve Body | -268℃~649℃ |

| 316L Stainless Steel Valve Body | -268℃~649℃ |

FAQ

Q: Are you a trading company or a manufacturer?

A: Yes, we are a professional ball valve manufacturer and can offer you the best price.

Q: Can you provide OEM services?

A: Yes.

Q: What about the packing?

A: Normally, we pack ball valves in plywood cases.

Q: What is the minimum order quantity ( MOQ )?

A: The amount for one order needs to be greater than 1000 dollars and the quantity of one size product needs to be exceed 10pcs.

Q: What are payment terms?

A:30% of the payment is required as a deposit, and the remaining balance must be paid before shipment.

Q: Are samples available?

A: Yes.

Metal seated floating flanged ball valve