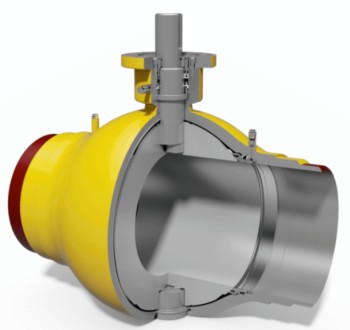

Fully Welded Ball Valve

JXON is a professional ball valves manufacturer. We can supply fully welded ball valves and other types of ball valves. If you want to know more information about fully welded ball valves, such as ball valve prices and delivery time, etc, please feel free to contact us.

What are fully welded ball valves?

JXON fullly welded ball valves are widely used in urban heat supply, urban gas, petrochemicals, steel, shipbuilding, regulating stations, power plants and other types of pipeline equipment. Espacially the fully welded gas ball valves, they are widely used in urban underground gas pipelines, natural gas transmission pipelines, pressure regulating stations and other fields. The seat of the fully welded ball valve is composed of a PTFE seal and butterfly type spring. The PTFE seal is reinforced with carbon fiber, making our fully welded ball valves well-suited to handle changes in pressure and temperature. If fully welded ball valves work within their rated pressure and temperature, there will be no leakage.

Based on the above features, fully welded ball valves can be buried in the ground without requiring a large valve well. This reduces project costs and also prevents personnel inury casued by operating the fully welded ball valve. Meanwhile, it can avoid the personnel injury caused by operating a fully welded ball valve. A fully welded ball valve can operate stablely for about 10 years under normal conditions.

What are the features of a fully welded ball valve?

1.Valve seat: The seat is made of 20% carbon and RPTFE material to ensure zero leakage (0%). The seat also has butterfly type springs, which allow the fully welded ball valves to adjust to pressure and temperature changes. For the fully welded ball valve seat, there are two options: soft seat and metal seat.

2.Valve ball: we use a computerized detector to track and detect the fully welded valve ball during the processing, resulting in high precision.

3.Valve body: There is no uneven stress since the valve material is the same as that of the pipe. The fully welded ball valves are resistant to deformation and aging, even in the event of a passing vehicle or an earthquake.

4.Valve stem: we can manufacture fully compliant valve stem according to the design standards or customers requirements. Directly buried fully welded ball valves can be buried in the ground without the need to built a large valve well. Only a small shallow well on the ground needs to be bulit, which greatly saves construction costs and time.

5.During the processing, we use various test procedures to inspect and ensure the good sealing. Additionally, visual inspection, magnetic particle testing, ultrasonic testing and radiographic testing are also conducted to inspect the welding line.

6.Fully welded ball valves can be classified into floating fully welded ball valves and trunnion-mounted fully welded ball valves. The Trunnion and stem transfer medium pressure, reducing friction between the ball and the seat and resulting in lower torque.

Applications:

1.Fully welded ball valve for city gas: gas output pipeline, main lines, and feeder supply pipeline, etc.

2.Fully welded ball valve for central heating: large output pipelines for heating equipment, including main lines and branch lines.

3.Fully welded ball valve for heat switch: opening and closing of pipes and circuits.

4.Fully welded ball valve for steel plant: all types of fluid pipelines, exhaust gas discharge pipelines, gas and heat supply pipelines, and fuel supply pipelines are included.

5.Fully welded ball valve for all kinds of industrial equipment: all types of heat treatment pipes and industrial gas and heat pipes are available.