Forged Steel Floating Ball Valve

JXON is the expert of manufacturing ball valves. Forged steel floating ball valve is our advantaged products. We can not only export complete ball valves but also export as parts.

- Port size :

- 1/2"-2"(DN15-DN50)

- Pressure :

- PN16-PN100(CL150-900)

- Structure :

- Floating Type

- Medium :

- water, petroleum, long -distance pipeline, chemical, paper making, pharmaceutical, electric and other applications

- Temperature :

- -29℃ ~ 425℃

- Body material :

- A105, F304, F316 Stainless Steel

- Connection :

- Flanged End

- Feature :

- 2PC, Forged, Soft Seated or Metal Seated

Forged Steel Floating Ball Valve

JXON is a professional manufacturer of ball valves. For forged steel ball valves, the valve body is forged. Compared to cast steel ball valves of the same size, the thickness of the forged ball valve is thinner due to its larger density and higher strength.

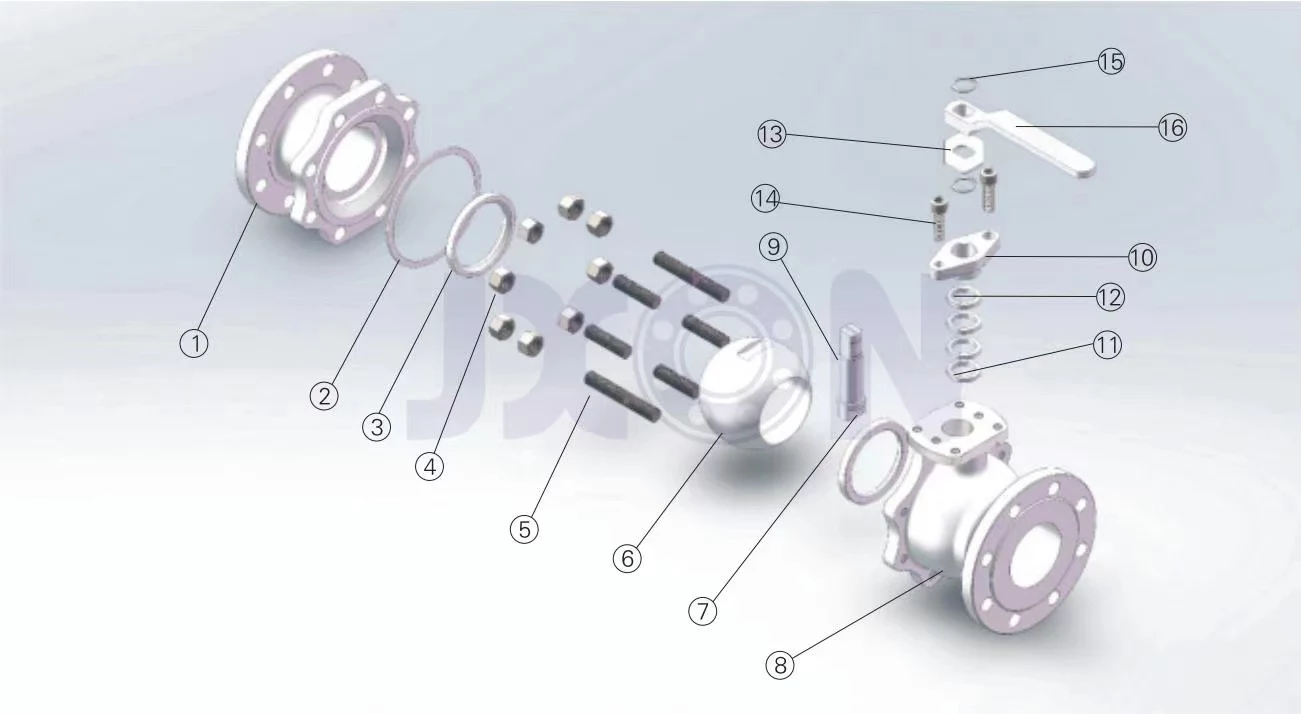

Materials of forged steel floating ball valves parts

| No. | Name of Part | Carbon Steel Series | Stainless Steel Series | Low Temperature Steel Series |

| 1 | Cap | A105 | F304/F316 | LF2/F304/F316 |

| 2 | Gasket | Graphite + Stainless Steel |

Graphite + Stainless Steel |

Graphite + Stainless Steel |

| 3 | Seat | PTFE, RPTFE | PTFE, RPTFE | PTFE, RPTFE |

| 4 | Nut | A194 2H | A194 8/8M | A194 7 |

| 5 | Bolt | A193 B7 | A193 B8/B8M | A320 L7 |

| 6 | Ball | A105+HCr/ENP | A182 F304/F316 | A182 F304 |

| 7 | Antistatic Device | Stainless Steel+Spring | Stainless Steel+Spring | Stainless Steel+Spring |

| 8 | Valve Body | A105 | F304/F316 | LF2/F304/F316 |

| 9 | Stem | A182 F6a | A182 F304/F316 | A182 F6a |

| 10 | Packing Gland | A105 | F304/F316 | LF2/F304/F316 |

| 11 | Back-up Ring | 304/316/Copper | 304/316/Copper | 304/316/Copper |

| 12 | Packing | Graphite+PTFE | Graphite+PTFE | Graphite+PTFE |

| 13 | Stopper | Q235A | Q235A | Q235A |

| 14 | Stud Bolt | A193 B7 | A193 B8/B8M | A320 L7 |

| 15 | Circlip | 65Mn | 65Mn | 65Mn |

| 16 | Handle | A216 WCB,Aluminium Alloy | A216 WCB,Aluminium Alloy | A216 WCB,Aluminium Alloy |

Main performance specifications of forged steel floating ball valves parts

| Nominal Diameter (CL) | CL150 | CL300 | CL600 | CL900 | |

| Test Pressure | Body Strength | 3.0Mpa | 7.5Mpa | 15.0Mpa | 22.5Mpa |

| High Pressure Seal (Water) | 2.2Mpa | 5.5Mpa | 11.0Mpa | 16.5Mpa | |

| Low Pressure Seal(Air) | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Suitable Temperature | -29℃~425℃ | ||||

| Media | Air, Steam, Water, Oil, Acid, Alkali, Salt, Etc.(media without excessive particle impurities.) | ||||

| Drive Mode | Handle, Worm Gear, electric actuator, Pneumatic Actuator, Hydraulic Actuator | ||||

forged steel floating ball valves parts features:

1.Jxon forged stianless steel ball valves can be either floating or trunnion type. Trunnion type forged ball valves are typically used for high pressure applications, while floating forged ball valves are suitable for low and medium pressure.

2.Two-piece and three-pieces valve body are available for forged stainless steel ball valves. The 3PC type is usually used for high pressure and large dimention applications.

3.During thermal cycling and deformation processes, the steel's grain moves, and forging causes metallurgical changes, recrystallization, and grain refinement. Forged steel undergoes stress-relief and improve impact and shear performance.

4.Triple protection design:

Anti-static device

Fire safe design

Blow-out proof

Standard of forged steel floating ball valves parts

| Standard Specifications for ANSI CLASS 150/600 Flanged Ball Valve | |

| Design and Manufacture Standard | API 6D/ASME B16.34 |

| Wall Thickness Standard | API 6D/ASME B16.34 |

| Face-to-Face Dimension Standard | API 6D/ASME B16.34 |

| Flange End Dimension Standard | ANSI/ASME B16.5 (1/2” to 2”) |

| Inspection & Testing Standard | API 6D/API 598 |

| Fire Safe Design Standard | API 607/BS 6755 |

| Material Standard | Nace MR 0175 |

| Standard Specifications for DIN PN16/40 Flanged Ball Valve | |

| Design and Manufacture Standard | EN1983, EN12516-1 |

| Flange End Dimension Standard | DIN2543-2545, EN1092-1, PN16/40 |

| Face-to-Face Dimension Standard | DIN3202-F1, EN558-1 |

| Inspection & Testing Standard | DIN3230, EN12266-1 |

Features of forged steel floating ball valves parts

| Full Port | 1/2"-2"(DN15-DN50) |

| Flanged End Working Pressure | PN16/100, Class 150/900 |

| Handle with Lock Device | Optional |

| ISO5211 High Platform | Optional |

Valve seat temperature of soft seated forged steel floating ball valves parts

| PTFE | -29℃~150℃ |

| PEEK | -50℃~250℃ |

| PPL | -40℃~260℃ |

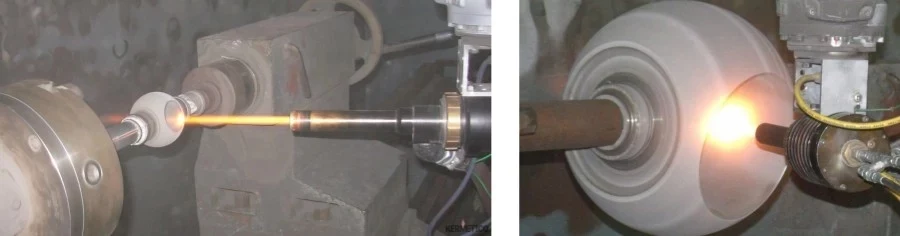

Supersonic spray of metal seated forged steel floating ball valves (HVOF,HVAF)

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.5-1.2mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.5-1.2mm |

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.4-0.8mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.4-0.8mm |

| Wolfram Carbide | HV950-1400 (HRC68-76) | Coating Thickness 0.15-0.25mm |

| Chromium Carbide | HV850-1150 (HRC66-72) | Coating Thickness 0.15-0.25mm |

| Nickel-based Alloy | HV600-860 (HRC55-65) | Coating Thickness 0.15-0.25mm |

| Cobalt-base Alloys | HV600-900 (HRC55-67) | Coating Thickness 0.15-0.25mm |

Valve body temperature of forged steel floating ball valves parts

| Carbon Steel Valve Body(WCB) | -30℃~425℃ |

| 304 Stainless Steel Valve Body | -268℃~649℃ |

| 304L Stainless Steel Valve Body | -268℃~649℃ |

| 316 Stainless Steel Valve Body | -268℃~649℃ |

| 316L Stainless Steel Valve Body | -268℃~649℃ |

Why choose JXON forged steel floating ball valves?

1. We have advantages in production cost and delivery time for this multi-directional die forged steel ball valve.

We compared our multi-directional die forged steel ball valve with similar products on the market and found that we can save at least 15% in cost. Because we have independently researched and developed multi-station drilling equipment, this equipment can produce 8 valve bodies at the same time. This greatly reduces drilling time and labor costs, as well as shortening delivery times.

2. At present, we have molds for multi-directional die forged steel ball valves ranging from DN15 to DN50(1/2"~2"). If you require a larger size, please do not hesitate to contact us. Our professional technical team will provide you with a solution.

FAQ

Q: Are you a trading company or a manufacturer?

A: Yes, we are a professional ball valve manufacturer and can offer you the best price.

Q: Can you provide OEM services?

A: Yes.

Q: What about the packing?

A: Normally, we pack ball valves in plywood cases.

Q: What is the minimum order quantity ( MOQ )?

A: The amount for one order needs to be greater than 1000 dollars and the quantity of one size product needs to be exceed 10pcs.

Q: What are payment terms?

A:30% of the payment is required as a deposit, and the remaining balance must be paid before shipment.

Q: Are samples available?

A: Yes.

Forged steel floating ball valve pictures