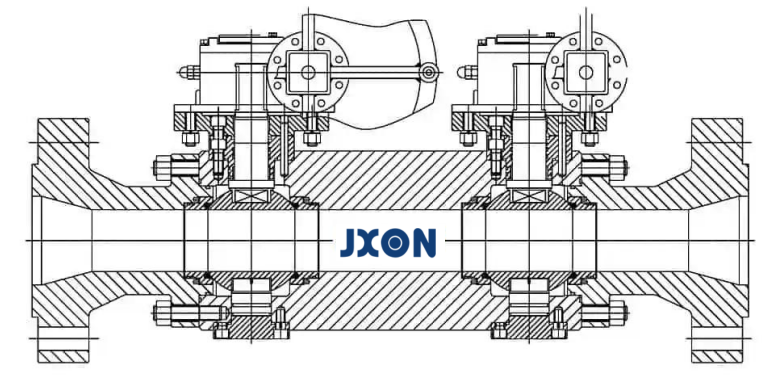

DBB Ball Valve

JXON is a professional ball valves manufacturer. We can supply both DBB ball valves and DIB ball valves. If you have any questions regarding selection, please feel free to contact us, our professional technical team can assist you.

What are DBB and DIB ball valves?

Different systems have different definitions for DBB (Double Block and Bleed) ball valves. Therefore, it is necessory to clarify these differences in order to prevent the customers from making incorrect selections.

The definition of a DBB ball valve by UK industry organizations: Two balls are integrated simultaneously into one valve body, and there is one or two drainage or emptying devices between the two balls. This means that when the pressure in the central cavity becomes excessive, any residual medium can be discharged through discharge device.

However, the US industry systems (API 6D) have different definitions for DBB ball valves. They even have a more detailed classification for DBB ball valve. They have devided the DBB ball valve into two types: DBB ball valve and DIB ball valve, DIB (Double Isolation and Bleed) ball valve, with the latter further divided into DIB-I ball valve and DIB-II ball valves.

DBB, DIB-I and DIB-II are all based on trunnion ball valves. As we know, for the trunnion ball valve, the ball is helded by the stem and trunnion, so it can not be displaced. But the seat is floating, which means that it can move under the medium pressure. The floating seat can also be divided into one-way and two-way seats. For a one-way seat, it can only move in one direction under mudium pressure. For a two-way seat, it can move in two directions under the medium pressure. When the seat move towards the ball, the seal will be strengthened.

On the contrary, the seat moves in the opposite direction of the ball, relieving pressure.

What are the differences between DBB, DIB-I and DIB-II?

DBB(Double Block and Bleed) ball valve: When closed, a single valve body with two balls can fully seal the upstream and downstream of the valve, while allowing for controlled release of pressure in the center cavity. Compared with the definition of UK industry organizations , we can see that even the pressure in the centre cavity can be released into the pipeline.

When the DBB ball valve is fully closed, the pressure in both upstream and downstream pipelines pushes the seats towards the ball, which are then held tightly by the seat to achieve double block function. This is the self-protection mechanism of the valve. When the pressure inside the valve becomes too high, the medium in the central cavity will be released through both upstream and downstream pipes. This means that when the pressure in the middle cavity is becomes too high, it is released into the inside of the pipe. This process is also known as valve self-relief or single picton effect.

DIB-I ball valve: This ball valve is different from a DBB ball valve. In a DBB ball valve, the seats can be pushed by medium pressure in the centre cavity and discharge residual medium to upstream or downstream pipes. The medium pressure in the centre cavity cannot push the seat of DIB-I ball valve. This is because the seats use a double piston effect design, which ensure that the seats remain in place even under high pressure. Thus, a discharge device needs to be installed to release pressure in the central cavity.

DIB-II ball valve: For one side, use a one-way seat (single piston effect seat) for upstream or downstream, and for the other side, use a two-way seat(double piston effect seat). When the pressure in the valve cavity is too high, the medium will be discharged to one end of the two-way seat.

DBB and DIB ball valves VS common ball valve

DBB and DIB ball valves are actually a combination of two common ball valves and one or two discharge valves. But what are the advantages of using DBB and DIB ball valves?

1.Firstly, DBB and DIB ball valves have the function of fluid flow control and blockage.

2.Combination the functions of three independent valves into one valve can save installation time and space.

3.There are fewer connection points, resulting in fewer leaks.

4.It has a double insurance function in the pipeline.

5.It is lightweight and cost-effective.