What are the fire-proof anti-static and anti-abnormal boost structures

Most of the valve seats and packings of ball valves are made of non-metallic materials such as rubber and fluoroplastics. When ball valves are used to transport flammable and explosive media such as petroleum, natural gas, and hydrogen, unexpected fires may occur. In this case, the polymeric sealing materials will soften or even burn, causing the ball valve to lose its sealing capability. Even when the ball valve is closed, it cannot effectively cut off the gas source, resulting in serious consequences.

During the opening and closing process of ball valves, the ball and the valve seat will generate static charges due to relative movement, and non-metallic materials such as rubber and plastics are excellent electrical insulators. When the static charges accumulate to a certain extent and in the presence of sparks, it may lead to explosions, which is particularly dangerous in situations where flammable and explosive media are being transported.

At the same time, when the ball valve is used to transport liquefied gas, when it is in the closed state, the liquefied gas trapped in the chamber between the valve and the valve seat will vaporize in large quantities due to absorbing external heat, causing abnormal increase in pressure inside the chamber. This abnormal pressure increase may lead to valve body explosion or the valve stem being pushed out of the body, resulting in accidents.

Therefore, when designing the ball valve, it is necessary to consider the fire resistance, anti-static and anti-abnormal boost structure of the ball valve.

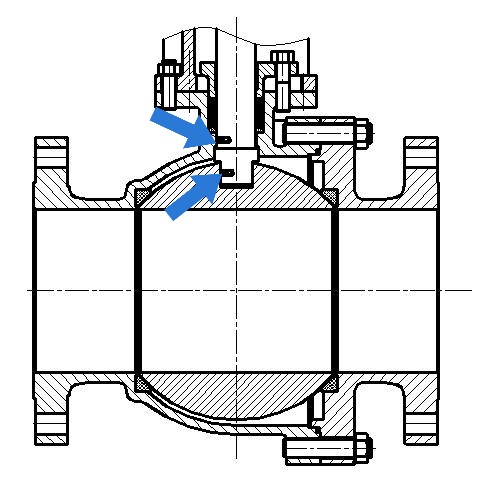

1. Fire-proof structure

Picture A

Picture B

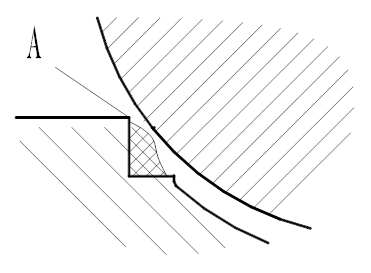

Picture A shows the structure of a common fire-resistant seat for floating ball valves. In the event of a fire, the high polymer material of the seat is burnt, and the ball of the valve, under the action of fluid pressure, will be pushed towards the rear seat of the valve, making temporary and partial sealing contact with the processed metal seat surface A, to prevent the escalation of the disaster.

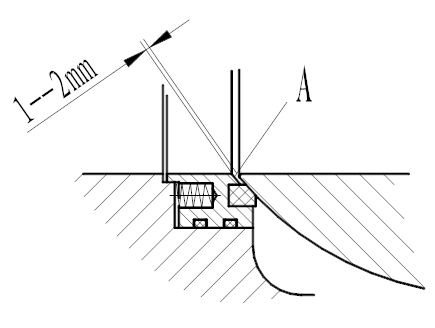

Picture B shows the structure of a common fire-resistant fixed ball valve. When the valve is in normal working condition, the high polymer material sealing element of the elastic seat maintains a seal with the ball. At this time, there is a 1-2mm gap between the ball and the floating support seat A on the elastic seat. Once the high polymer sealing element is burnt or softened, the elastic seat will be pushed towards the ball under the pressure of the fluid, making contact with the pre-processed metal sealing surface A, providing temporary and partial sealing. After the disaster is resolved, it can be repaired or replaced.

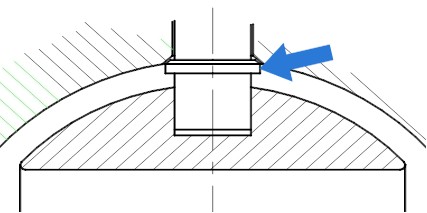

Ball valves used for conveying flammable and explosive media should be designed with a fire-resistant valve stem sealing structure, as shown in the diagram below. In the event of a fire, when the soft packing is burnt or softened, the fluid pressure in the valve body cavity will push the valve stem towards the valve body, and the shoulder on the valve stem will be blocked by the valve body, and will be tightly pressed and sealed by the high-pressure fluid pressure. Additionally, it can also prevent the valve stem from being ejected when there is abnormal pressure rise in the cavity.

2. Anti-static structure