What are differences between O-type and V-type ball valves?

V-type and O-type ball valves are both types of ball valves. The two types of ball valves have different structures and characteristics, and are suitable for different operating conditions. By analyzing the differences and characteristics of the two, they can be better understood and used, providing assistance in selecting the appropriate product.

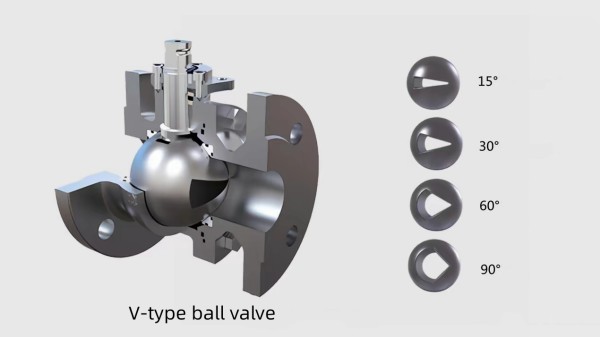

1. Structure and characteristics of V-type ball valves

V-type ball valves are highly efficient valves with a unique design, characterized by a V-shaped opening on one side of the semi-spherical valve core. By adjusting the opening of the valve core, the cross-sectional area of the medium flow can be effectively changed, achieving precise flow control. It can also be used for on/off control to open or close pipelines. This valve has a self-cleaning function, capable of regulating tiny flow within a small opening range, with a large adjustable ratio. It is suitable for media containing fibers, fine particles, and pulp. It offers high reliability and stability, and is an indispensable component in the field of fluid control.

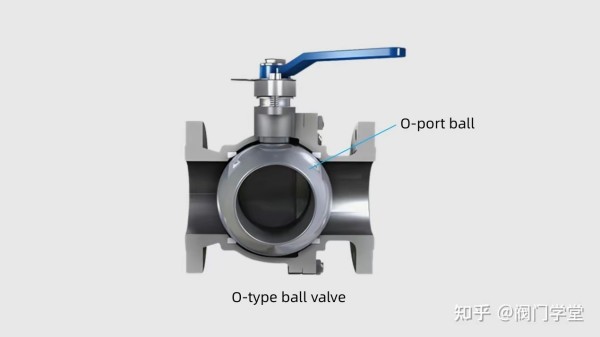

2. Structure and characteristics of O-type ball valves

The ball core of O-type ball valves is a solid sphere, and the flow passage is circular, hence the name O-type ball valve. The majority of ball valves we use are O-type ball valves. They have low flow resistance, and the switching process only requires a 90-degree rotation of the valve core, resulting in fast switching speeds. They can be equipped with AT cylinders for use as fast shut-off valves. They have two seat seals at the inlet and outlet, ensuring reliable sealing. They can be used for gases, steam, liquids, and media with a small amount of suspended particles.

3. Differences between V-type and O-type ball valves.

1)The valve core structures are different. The flow passage of the O-type ball valve is a complete circle, equipped with double seat seals. The V-type ball valve uses a 1/4 semi-spherical valve core, with a V-shaped opening on one side, and adopts a single seat seal. There are also designs with a fully spherical valve core, with a V-shaped flow passage opening on one end, using a single seat seal or double seat seal.

2)They are suitable for different media. O-type ball valves are mostly used for clean media or media with a small amount of suspended particles. When using PTFE seals, zero leakage can be achieved. However, when the media contains a higher amount of impurities or particulate matter, blockage in the chamber can easily occur, leading to valve jamming and malfunction. V-type ball valves mostly use metal hard seals and are suitable for media containing fibers, fine particles, and pulp. Since the V-shaped opening can shear the fiber media, they are widely used in the paper industry. The use of a partially spherical valve core and a single seat seal effectively prevents media blockage in the valve.

3)They have different process control requirements. O-type ball valves are mainly used for on/off control, with poor regulating performance. When equipped with AT pneumatic piston actuators, quick shut-off can be achieved. V-type ball valves have V-shaped openings, providing good adjustability and large adjustable ratios, up to 100:1 or higher. When equipped with pneumatic and electric actuators, they are mainly used for regulating control, but can also be used for on/off control.

4)They have different flow characteristics. The flow characteristic of O-type ball valves is quick opening, suitable for on/off control. The flow characteristic of V-type ball valves is approximately equal percentage, suitable for regulating control.

5)They have different flow passage sizes. O-type ball valves generally have two types of flow passage sizes: full bore and reduced bore. The flow passage size of V-type ball valves varies according to the process and design requirements, usually being reduced bore. Different ball cores can be replaced to meet different flow rate requirements.