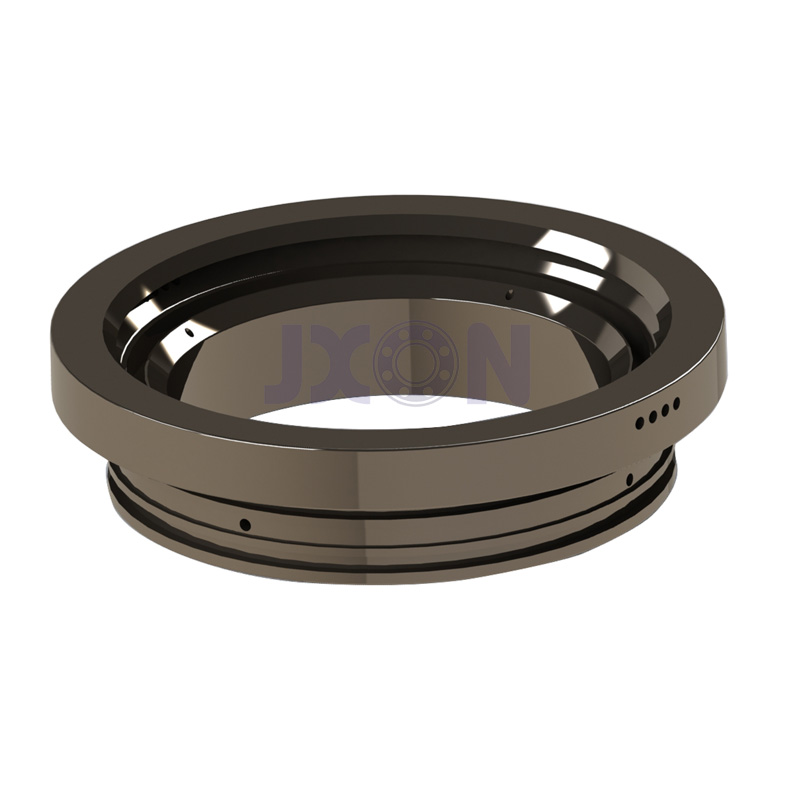

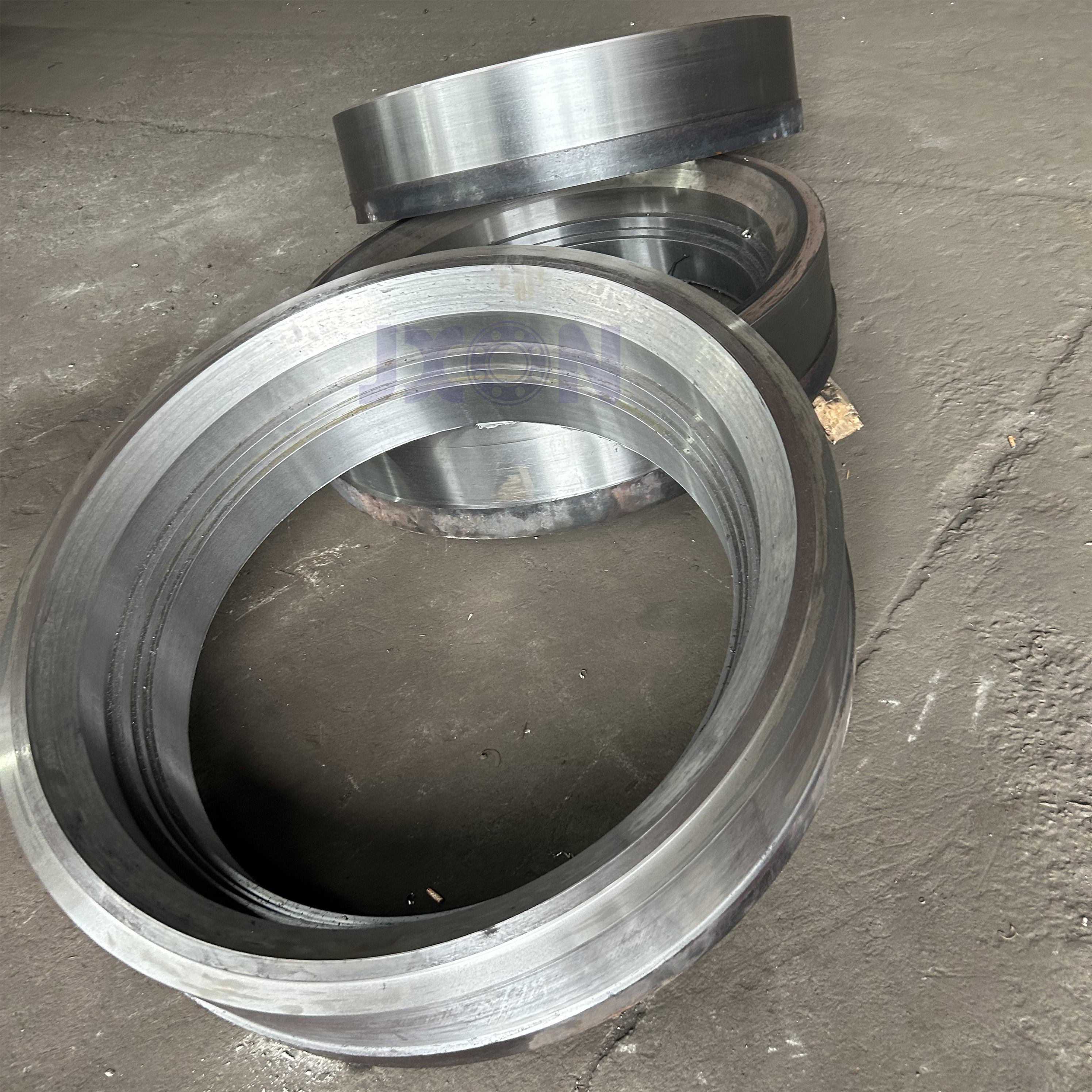

Valve Seat

We can process the valve seats according to customers' drawings and requirements, using infrared precise positioning to ensure drilling accuracy.

- Port size :

- DN50~DN500

- Feature :

- Drilling depth: 10~50mm, Drilling diameter:2~5mm

Our Metal Seat Advantages

The matel seats (also known as hard seats ) made by different manufacturers look similar, and it is hard to distinguish their quality. For a metal seat, the most important thing is drilling holes. As we know, there are several grease injection holes and exhaust vents. If manual positioning is used, it may cause the hole position to be offset, resulting in the grease injection hole not opening. However, with infrared positioning, there is no miss in positioning accuracy. The grease injection hole can be tested by blowing compressed air into it.

Additionally, our valve seat production is twice that of conventional processing. Traditionally, electrical pulse punching is used which resulting in slow punching speed. However, we use self-developed punching equipment enables us to punching stronger and faster.

We can manufacturer metal seats based on customer's drawings.