Ball Valve Body Parts

Generally, people think the body strength of a forged steel ball valve is higher than that of a cast steel ball valve, and forged steel ball valves do not have any defects such as an incompact structure or a great deal of sand holes on the surface. However, the purchased cost of forged steel ball valve is higher than that of cast steel ball valves. Therefore, when the budget is limited, people still tend to choose cast steel ball valves. Although, cast steel ball valves have a lower purchase cost, actually they also have higher maintenance cost. JXON offers forged steel ball valves with a lower budget than cast steel ball valves.

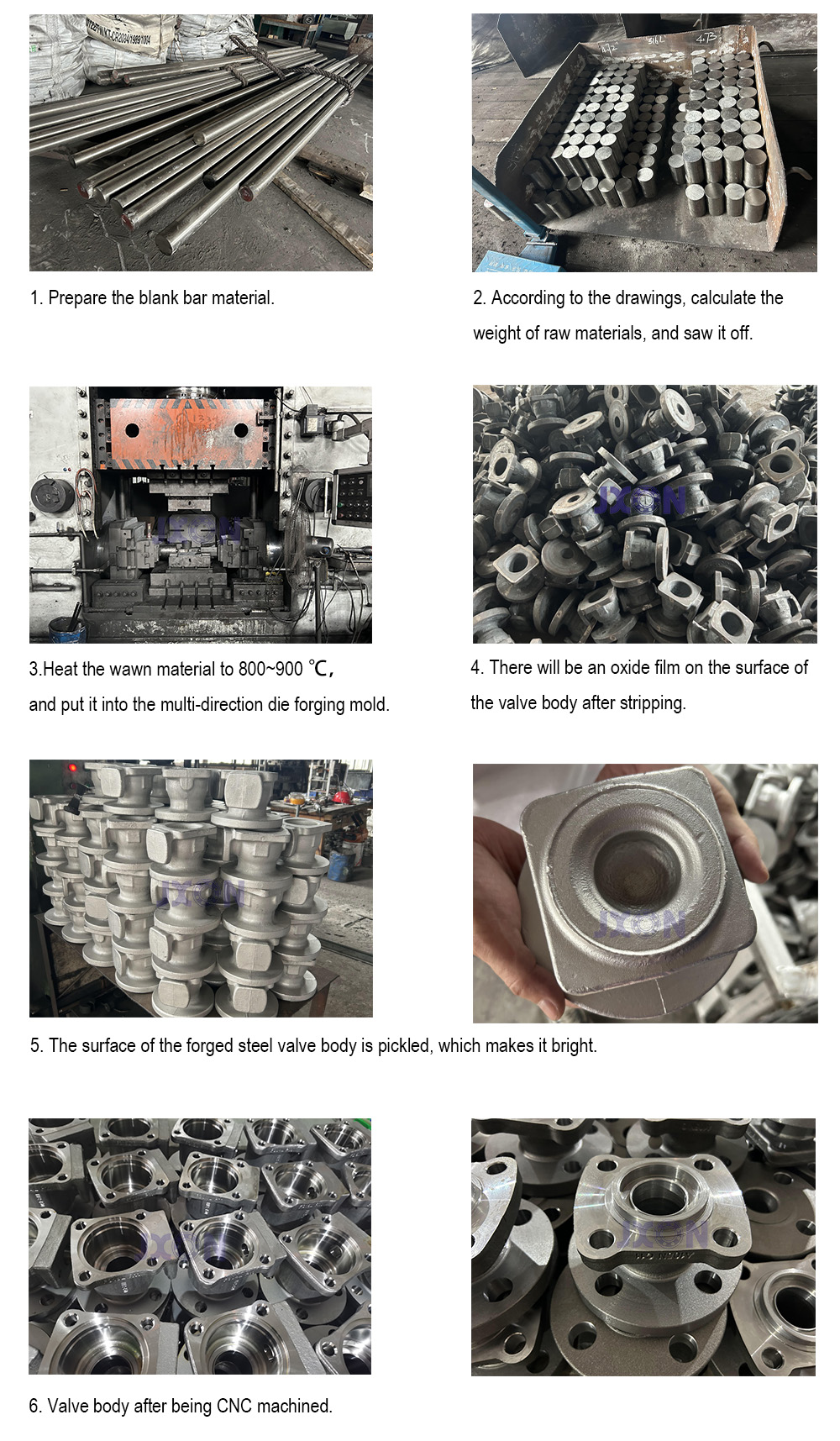

JXON focuses on providing higher quanlity ball valves, while reducing procustion cost. Forged steel ball valves are our advantageous products. The reason for the high production cost of forged steel ball valves is that a forged steel ball valve body requires more production time and has more spare material than cast steel ball valves. Typically, one CNC machine can only produce one valve body at a time, resulting in a very low processing efficiency and long production times. Due to its long production time, JXON has developed a special equipment for forging valve drilling. This special equipment can produce nine valve bodies simultaneously with a large drilling force and high efficiency, greatly reducing the processing time for forging valve bodies. Regarding the issue of excess material, we utilize multi-directional closed die forging. As is known, this method produce no flash and waste few spare material, resulting in a valve body that is nearly finished. It only requires a minor CNC machining. Therefore, we can greatly reduce the time and raw material costs, which gives us the advantages in terms of pricing and delivery time.

Due to changes in the trend of the international trade, some countries or regions prefer to import or export ball valve parts. In order to meet customers' requirements, we can export various types of ball valves and ball valve parts according to clients needs and also process them based on the drawings.

Forged steel ball valve body production process